06

2025

-

09

Smart Film Products: How Label Films with QR Codes Achieve Traceability

Author:

Chinafilm Group

Preface

In today's era of rapid commodity circulation and fierce market competition, product traceability functions are becoming increasingly critical:

- Consumers' attention to product quality and safety continues to rise, eager to obtain full-process information;

- Enterprises need to manage circulation effectively, maintain brand image, and avoid counterfeit risks;

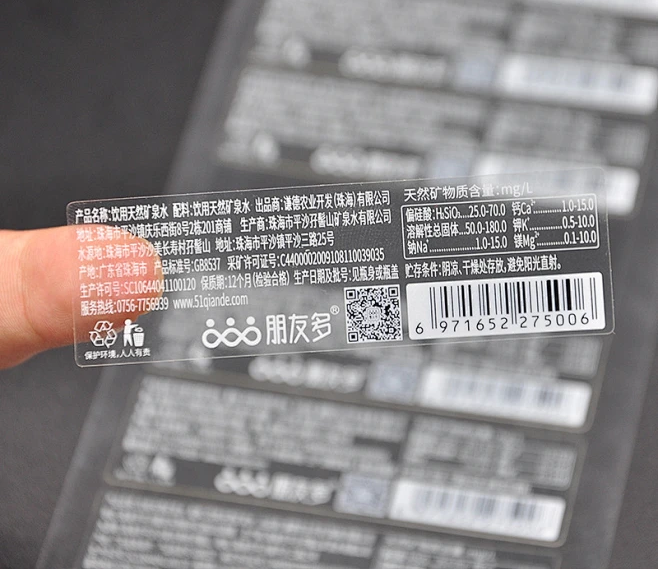

- QR code label films, as core products of smart films, act like a "digital ID card" for each product, allowing clear viewing of the entire process from production to sales by scanning the code.

Next, we will analyze the traceability logic of QR code label films from four dimensions: principles, processes, advantages, and cases.

1. Traceability Principle of QR Code Label Films: Three Core Supports

(1) QR Code: High-capacity "Information Carrier"

1. Technical Features : Matrix-type two-dimensional barcode, capable of storing information both horizontally and vertically, unlike one-dimensional barcodes that only store horizontally;

2. Capacity Advantage : A single ordinary QR code can hold thousands of characters, covering key data throughout the product lifecycle, for example:

- Production end: production date, batch number, production location, process parameters;

- Raw material end: raw material source, supplier qualifications, component ratios;

- Testing end: quality inspection report number, test item results.

(2) One Product One Code: Precise Traceability "Unique Identifier"

1. Coding Rules : Enterprises generate unique codes through exclusive systems; each QR code corresponds to one product, with no duplicates or reuse;

2. Information Binding : Product information is associated with the QR code synchronously during production, forming a one-to-one "code-product-data" relationship;

3. Query Logic : When scanning the QR code, the system accurately retrieves the corresponding product information from the database via the unique code, avoiding information confusion.

(3) Data System: The "Backend Hub" of Traceability Function

1. System Composition : Composed of database servers, data management software, and information transmission interfaces;

2. Data Collection Scope : Covers the entire product lifecycle, including:

- Procurement stage: raw material purchase time, inbound inspection data;

- Production stage: equipment operating parameters, process completion time;

- Logistics stage: storage location, transportation routes, transfer nodes;

- Sales stage: terminal stores, sales time, sales assistant information;

3. Data Update Mechanism : Real-time data collection and synchronous uploading at each stage to ensure timeliness and accuracy of information.

2. Working Process of QR Code Label Films: Four Steps to Complete Full-chain Traceability

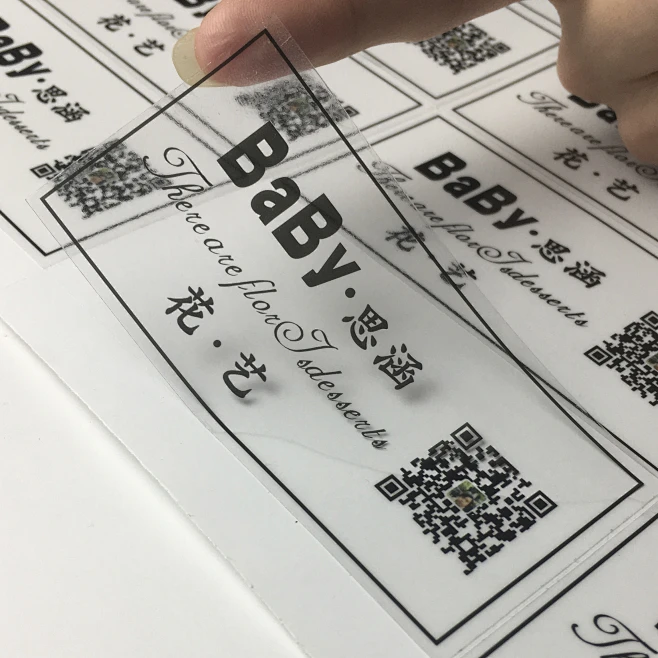

(1) Preparation: Customizing Label Films + Establishing Coding Rules

1. Label Film Customization :

- Collaborate with professional printing manufacturers to select suitable film materials based on product packaging materials (such as plastic, metal, paper);

- Ensure QR code printing clarity to meet scanning needs in different scenarios (such as strong light, humid environments);

2. Coding Rule Establishment :

- Determine core information included in the code (such as brand code, production year, serial number) based on enterprise product characteristics;

- Interface with data system to test the stability of code generation and information binding.

(2) Code Assignment in Production: Automated "Code-Product" Binding

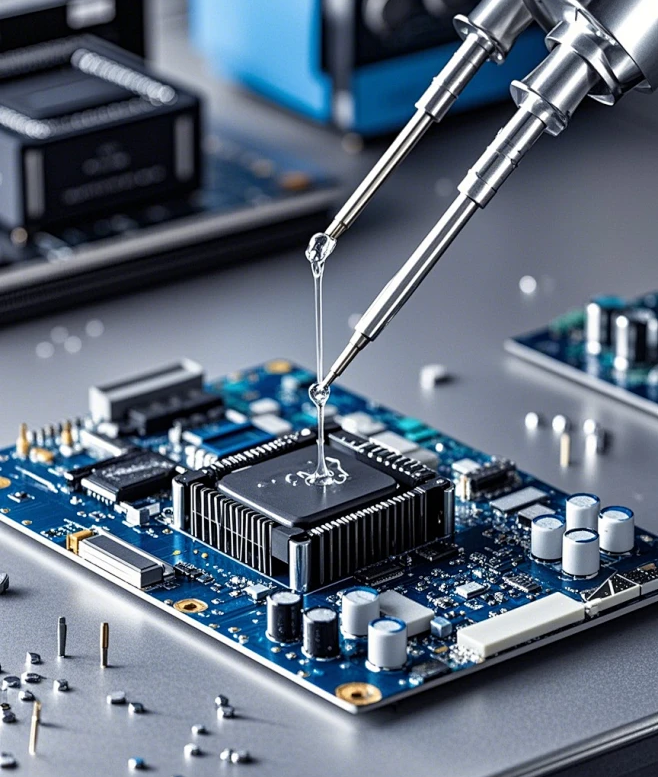

1. Code Assignment Equipment Selection :

- Labeling machines: suitable for flat surfaces like cosmetic bottles, food packaging boxes;

- Laser coding machines: suitable for wear-resistant materials like electronic product shells, metal containers;

- Inkjet printers: suitable for mass-produced flexible packaging (such as plastic bags, aluminum foil bags);

2. Synchronous Binding Operation :

- Trigger production system during code assignment to automatically bind product model, production batch, operator information with the QR code;

- After binding, data is uploaded in real-time to the data management system, forming the initial traceability record.

(3) Full-chain Data Collection: Real-time Recording of Each Key Node

Stage | Collection Equipment | Collected Information | Upload Frequency |

Production Stage | Sensors, barcode scanners | Equipment temperature/pressure, component usage status | Real-time |

Storage Stage | RFID readers | Inbound time, inventory location, outbound batch | Batch update |

Logistics Stage | GPS positioning, barcode scanners | Transport vehicle information, transfer stations, arrival time | Node-triggered update |

Sales Stage | Cash register system, barcode scanners | Sales store, sales time, purchaser information (optional) | Upload immediately after transaction completion |

(4) Consumer Inquiry: Obtain Full-process Information in 30 Seconds

1. Steps for QR Code Scanning Operation :

- Open the QR code scanning app on your phone (WeChat, Alipay, or the browser's built-in scanning function);

- Aim the camera at the QR code on the product packaging, keep the lens steady, and complete the scan;

2. Information Display Content :

- Basic Information: Brand name, product specifications, shelf life;

- Traceability Information: Source of raw materials, photos of the production workshop, logistics tracking map;

- Guarantee Information: Quality inspection report, after-sales contact information, recall notices (if any).

3. Three Core Advantages of Traceability Function with QR Code Label Film

(1) For Consumers: Dual Enhancement of Right to Know and Sense of Security

1. Information Transparency No professional knowledge required; scanning the QR code allows intuitive viewing of the entire product process information, ending the "information black box";

2. Convenient Anti-counterfeiting Identification :

- If scanning yields no result or the information does not match the product, counterfeit products can be quickly identified;

- Some companies set up "scan count warnings," where multiple scans of the same QR code will prompt a risk alert.

(2) For Enterprises: Dual Drivers of Cost Reduction & Efficiency Improvement + Brand Value Enhancement

1. Production Optimization :

- Use traceability data to locate weak points in production (e.g., if a batch has a low pass rate, it can be traced to specific equipment parameters);

- Analyze raw material usage data to optimize procurement plans and reduce waste;

2. Supply Chain Management Upgrade :

- Real-time tracking of inventory dynamics to avoid overstock or shortages, reducing storage costs;

- In case of quality issues, lock down the affected batch range within 10 minutes to minimize recall losses;

3. Brand Image Enhancement :

- Convey the brand philosophy of "valuing quality and embracing transparency" to the market;

- Some consumers develop brand preference due to traceability features, increasing repurchase rates.

(3) For the Industry: Promoting Standardization and Digital Transformation

1. Combating Counterfeits and Inferior Products Increase the cost of counterfeiting (requiring copying the QR code plus forging the entire data set), purifying the market environment;

2. Supporting Regulatory Collaboration Regulatory authorities can retrieve enterprise traceability data through the system to efficiently conduct quality spot checks;

3. Promoting Industry Standard Unification Forcing small and medium enterprises to upgrade their traceability systems, improving the overall digital level of the industry.

4. Three Industry Application Cases: From Theory to Practical Implementation

(1) Food Industry: "Milk Source Visualization" Solution for a Milk Powder Brand

1. Enterprise Actions A domestic milk powder brand attaches QR code label films inside the lid of each can;

2. Traceability Highlights :

- Scanning the code allows viewing of real-time monitoring footage of the milk source farm (updated three times daily);

- Displays dairy farmer qualification certificates and fresh milk test reports (including protein content, antibiotic residues, etc.);

- Logistics stage shows real-time temperature curves of the transport compartment to ensure safe storage of milk powder;

3. Effect Feedback Consumer satisfaction increased by 28%, complaints about counterfeit products decreased by 65%.

(2) Electronics Industry: "After-sales Traceability" Solution for a Mobile Phone Brand

1. Enterprise Actions A mobile phone brand laser-engraves a QR code on the back of the phone, linked to the motherboard serial number;

2. Traceability Highlights :

- Consumers scanning the code can view component suppliers (such as screen and battery brands) and assembly workshop information;

- During after-sales repair, engineers can scan the code to retrieve factory test data and repair history of the phone;

- In second-hand transactions, scanning verifies whether the phone is original and if it has any repair history;

3. Effect Feedback After-sales repair efficiency improved by 40%, and the premium rate for original phones in the second-hand market increased by 15%.

(3) Beauty Industry: "Ingredient Traceability" Solution for a Skincare Brand

1. Enterprise Actions A skincare brand attaches scratch-off QR code label films on the outside of the packaging box (to prevent premature scanning);

2. Traceability Highlights :

- Scanning displays the sourcing locations of core ingredients (such as French grape seeds, Japanese hyaluronic acid) and extraction processes;

- Provides short educational videos on ingredient efficacy to enhance consumer trust;

- Scanning allows participation in "points redemption," increasing user interaction rates;

3. Effect Feedback New product repurchase rate increased by 32%, user scan interaction rate reached 45%.

5. Conclusion: From "Traceability" to "Full-Chain Intelligent" Future

QR code label films are not only "product traceability tools" but also the "entry point" for enterprise digital transformation. Currently, they solve the core pain point of "information asymmetry," connecting consumers, enterprises, and regulatory authorities; in the future, with the integration of IoT and AI technologies, they will realize more functions:

- Intelligent Alerts: Automatically push reminders to consumers when products approach their expiration date;

- Personalized Services: Recommend suitable product usage plans based on consumers' scanning habits;

- Carbon Footprint Traceability: Record carbon emissions during product production and transportation to support green consumption.

As an innovative representative of intelligent film products, QR code label films are reconstructing the "product trust system." It is believed that in the future, they will penetrate more industries (such as pharmaceuticals, building materials, agricultural products), injecting more momentum into building a safe, transparent, and efficient business environment.

Latest News

2026-03-06

A Must-Read for Film Manufacturers! Why Are Most Multi-layer Film Bags Made with an Odd Number of Layers? The Truth Lies in the Manufacturing Process.

Many membrane manufacturers blindly pursue even-numbered layers, which not only drives up costs but also makes the membranes more prone to delamination and warping. From a practical industry perspective, this article breaks down the core reasons in detail, striking a balance between technical depth and practicality. It’s tailored for membrane manufacturers’ production processes, customers’ product selection, and newcomers’ learning—packed with valuable insights and presented in a clear, organized manner.

2026-03-05

Plastic bottles can be spun into clothing—so why can’t plastic bags? A comprehensive explanation of the truth behind film and textile recycling.

Given that both are plastics, why can plastic bottles be recycled into clothing, while plastic bags are hardly ever used for spinning yarn and weaving fabric? As a public account focused on membrane materials, today we’ll thoroughly explain this issue from five perspectives: the intrinsic nature of the materials, their structural characteristics, recycling processes, industrial chain dynamics, and current industry realities.

2026-03-01

Who would have thought! The toothpaste you squeeze every day comes in packaging that’s actually made of laminated film.

From the perspective of the membrane industry, this article dissects the structure, core advantages, and type differences of toothpaste composite membranes. It strikes a balance between popular science and technical expertise, offering practical insights that are easy to understand and suitable for both colleagues in the membrane industry and general readers.

2026-02-26

Don't use plastic bags carelessly! Here are 4 tips to spot the trickery in the innermost layer material in just 5 seconds.

Supermarket shopping bags, takeout bags, snack bags, and the like have long been integrated into daily life. Most plastic bags feature a multi-layer composite structure, and the material of the innermost layer directly determines their safety, food-contact suitability, and intended use scenarios.

2026-02-17

Chinafilm Group: Embarking on a New Journey with Practical Action, Building a Brilliant Chapter with Our Original Aspirations.

With the Golden Horse raising its head and ushering in a new era, all things are renewed and a splendid chapter is written. On this occasion of the Spring Festival in the Year of the Fire Horse (Bingwu), all colleagues at Chinafilm Group extend our warmest New Year greetings to our clients, partners, and friends from all walks of life who have silently supported us throughout the years—thank you for your enduring companionship and cooperation!