All Categories >

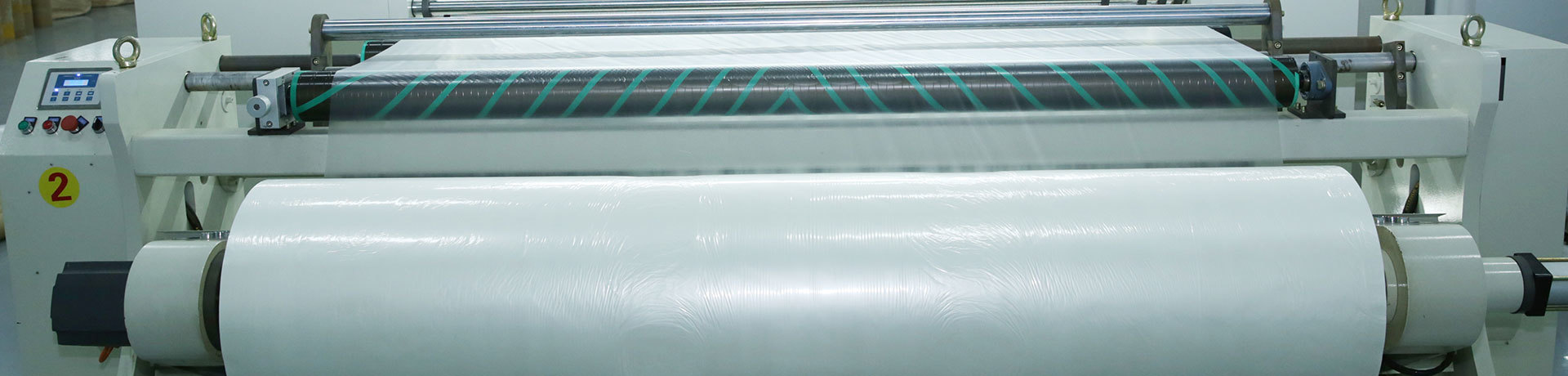

PET aluminized pre-coating film

Product advantages:

1. Greatly reduce the amount of aluminum, save energy and materials, and reduce costs. The thickness of aluminum foil for composite is mostly 7 ~ gpm, while the thickness of aluminum layer of aluminized film is about 0.05n, the aluminum consumption is about 1/140~1/180 of aluminum foil, and the production speed can be as high as 450 m/min.

2. It has excellent folding resistance and good toughness, rarely appears pinholes and cracks, no crumpled cracking phenomenon, so the barrier to gas, water vapor, odor, light and so on is improved.

Classification:

Details

Specifications:

|

ITEM |

PET METALLIZED THERMAL LAMINATING FILM 镀铝预涂膜 |

|

THICKNESS |

24 um (12 an aluminized film 12 an EVA glue) |

|

COLOR |

Silver, gold |

Product advantages:

1. Greatly reduce the amount of aluminum, save energy and materials, and reduce costs. The thickness of aluminum foil for composite is mostly 7 ~ gpm, while the thickness of aluminum layer of aluminized film is about 0.05n, the aluminum consumption is about 1/140~1/180 of aluminum foil, and the production speed can be as high as 450 m/min.

2. It has excellent folding resistance and good toughness, rarely appears pinholes and cracks, no crumpled cracking phenomenon, so the barrier to gas, water vapor, odor, light and so on is improved.

3. has excellent metallic luster, light reflectivity of up to 97%; and can be treated by coating to form a color film, the decoration effect is less than aluminum foil.

4. The shielding type can be partially aluminized to obtain any pattern or transparent window, and the contents can be seen.

5. Aluminum layer has good conductivity and can eliminate electrostatic effect; its sealing performance is good, especially when packaging powdered products, it will not pollute the sealing part, ensuring the sealing performance of the packaging.

6. It has good adaptability to post-processing such as printing and compounding.

Product Features

Scope of Application

Other Products

I want to consult