13

2025

-

09

Is your stretch film running out faster? Here's how to spot the "thick film, short length" trick!

Author:

Chinafilm Group

Preface: Don't Let "Thick Film" Steal Your Usage Amount

In logistics, industry, and e-commerce, stretch film is key to protecting goods, but the chaos of "thick film and short length" is frequent.

A Chongqing auto parts factory purchased 3,000 rolls of "15μ, 300 meters" stretch film in April 2024, planning to support 2 months of production. However, 2,000 rolls were consumed in just 1 month, only packaging 200,000 parts boxes (original plan was 375,000). Testing showed actual thickness was 18.2μ and length only 248 meters per roll. The company had to urgently buy 1,400 more rolls, incurring an extra cost of 11,900 yuan plus 50,000 yuan loss from production line downtime, totaling a loss of 61,900 yuan.

Today, combining practical experience, we teach you how to avoid the "thick film and short length" trap.

1. Must do before acceptance: Clarify 3 core indicators (with standards and common tricks explained)

Before unboxing, verify "thickness, length, unit area weight" to avoid some merchants exploiting loopholes. Below is a comparison of national standards and common tricks:

Core Indicators | National Standard (GB/T 12025-2021) Requirements | Some Merchants' "Thick Film and Short Length" Tricks | Interpretation of Indicator Importance |

Thickness Deviation | Allowed ±1μ, actual thickness must be marked, deviation not exceeding ±5% of contract |

3. Using vague description like "thickened type" | A 15μ, 300-meter film thickened to 18μ reduces length to 250 meters per roll. For a company consuming 20 rolls daily, this costs an extra 748 yuan monthly and over 8,900 yuan annually. |

Length per Roll | Allowed ±2%, if priced by weight must mark "length per kilogram" | 1. Marked 300 meters but actual 220-260 meters, short length rate over 30%; 2. Concealing "length per kilogram" to mislead weight-to-length relation; 3. Increasing core diameter to visually hide short length | Marked 300 meters but actual 250 meters increases film cost per box by 20.6%, requiring purchase of 200 extra rolls per 1,000 rolls, costing an additional 17,000 yuan. |

Unit Area Weight | Must match thickness and length (15μ film about 13.8g/㎡) | 1. Over 30% (e.g., 18g/㎡), effectively thickened to 19.8μ; 2. Misleading with "higher weight means more durable"; 3. Contradictory markings (15μ + 18g/㎡) | Excess weight causes film consumption to increase by 32.9%, indirectly shortening length and increasing usage frequency. |

2. Three-step on-site detection method: Identify "thick film and short length" in 5 minutes

Step 1: Thickness Detection (Prevent "thickening", 3 methods)

Method 1: Professional Tools (Digital Caliper)

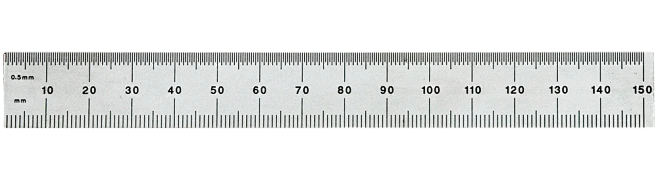

- Tools: Digital caliper (0.01mm accuracy, i.e., 0.1μ accuracy), scissors, marker

- Steps:

- For purchases ≤100 rolls, sample 5 rolls; for >100 rolls, sample 5% covering different positions;

- Cut 3 samples of 10cm×10cm per roll (5 meters from outer layer, one each top/middle/bottom);

- Measure 4 corners + center (5 times total) per sample, calculate average thickness;

- If over standard (e.g., marked 15μ but actual ≥16μ) or difference within same roll >0.5μ, judge as unqualified.

Method 2: Simple Tools (Standard Sample + Electronic Scale)

Steps:

- Take standard sample (e.g., middle film 15μ) and sample to be tested (same width and length);

- Weigh and calculate thickness: Tested thickness = (Test weight ÷ Standard weight) × Standard thickness;

- Example: Standard 15μ (13.8g), tested 16.6g, calculated 18μ (over standard).

Method 3: Comparative Observation (Strong Light)

Steps:

- Place standard and test samples side by side, illuminate with strong light;

- If test sample is less translucent and feels hard, thickness is over standard;

- Stretch twice; thick film rebounds slowly and delaminates easily (qualified film rebounds in 2 seconds without delamination).

Step 2: Length Detection (Prevent "short length", 3 methods)

Method 1: Weight Conversion (Accurate)

- Tools: Electronic scale (1g accuracy), calculator

- Steps:

- Read "marked thickness + width + marked weight", note polyethylene density 0.92g/cm³, core weight assumed 150g;

- Film weight = marked weight - core weight (e.g., 2.07kg - 0.15kg = 1.92kg);

- Calculate length: L (meters) = film weight (g) ÷ (thickness × width × 0.92) ÷ 100 (thickness unit conversion: 1μ=0.001mm=0.0001cm);

- If marked 300 meters but calculated ≤294 meters, judge as short length.

Method 2: Roll Diameter Measurement (Quick Estimate)

Steps:

- Measure total roll diameter (D) and core diameter (d);

- Film layer thickness = (D - d) ÷ 2;

- Comparison of the same specifications: For example, a 15μ middle film, 300-meter roll with a total diameter of 32cm, measured at 29cm, the actual length is calculated to be approximately 262.5 meters (short meters).

Plan 3: Length Calculation (Simplified)

Steps:

- Randomly select a roll of stretch film

- Measure the weight of the stretch film (gross weight)

- Use the roll of stretch film normally

- Then weigh the remaining paper core to get the net weight of the stretch film:

- Mass = Length * Width * Height * Density

(Treat the stretch film as a very long, very thin rectangular prism)

For example: The gross weight of the roll is 5kg, the paper core weighs 280g, the stretch film width is 50cm, thickness is 20μm, (stretch film density is generally 0.92g/cm³)

That is, the length of the stretch film is: (5000g - 280g) ÷ 0.92g/cm ÷ 50cm ÷ 20μm ≈ 526m (note unit conversion)

Step 3: Usage Efficiency Test (Prevent "Fast Consumption")

Manual packaging (e-commerce / parts boxes)

Steps:

- Set standards (e.g., 40cm box, wrap 3 turns, overlap 1/3);

- Package 10 items, calculate unit film consumption (meters/item);

- If 10% higher than standard (e.g., 0.5 → 0.55 meters/item), judged as unqualified.

Mechanical packaging (pallets)

Steps:

- Set parameters (stretch ratio 2:1, wrap 8 turns, 30% overlap);

- Package 5 pallets, calculate film consumption per pallet;

- If 10% higher than standard or total roll packaging amount is 10% less, judged as unqualified.

Tips: 1. Beware of sellers avoiding discussion of "length / price per meter"; 2. Be cautious if packaging lacks core data; 3. Calculate "unit length cost" to avoid being fooled by low price per roll.

3. Case Analysis

Case 1:

A manufacturing factory purchases 10 tons/month of stretch film with a thickness of 30μm, but the supplier provides 40μm thickness. The users noticed improved film quality but did not realize the thickness increased by 33%, resulting in a 33% increase in monthly purchase volume and overall stretch film cost rising by more than 33%.

Case 2:

A large factory's stretch film weighs 5KG gross per roll, with a purchase price of 9.8 yuan/KG. The factory's technical standard requires the paper core to be ≤1KG. Currently, the supplier delivers stretch film with a net film weight of 4KG and a paper core weight of 1KG. The paper core price is 6 yuan/KG, making the net film price 10.75 yuan/KG, much higher than the usual quote.

Conclusion: Master key inspection points to avoid the risk of "thick film short length"

Although the "thick film short length" issue is hidden, mastering scientific inspection methods can effectively avoid it. From clarifying the three core indicators "thickness, length, unit area weight" before acceptance, to on-site "thickness detection, length conversion, usage efficiency testing" in three steps, each step helps enterprises reduce hidden cost losses.

The editor hopes to share practical inspection knowledge with more companies through this popular science content, helping everyone avoid detours and pitfalls when purchasing. Whether in logistics packaging, industrial production, or e-commerce warehousing, as long as the principle of "inspect before use" is remembered and professional methods are used to verify product quality, stretch film can truly play its role in protecting goods and reducing costs while improving efficiency.

Stretch film,Procurement Skills

Latest News

2026-02-17

Chinafilm Group: Embarking on a New Journey with Practical Action, Building a Brilliant Chapter with Our Original Aspirations.

With the Golden Horse raising its head and ushering in a new era, all things are renewed and a splendid chapter is written. On this occasion of the Spring Festival in the Year of the Fire Horse (Bingwu), all colleagues at Chinafilm Group extend our warmest New Year greetings to our clients, partners, and friends from all walks of life who have silently supported us throughout the years—thank you for your enduring companionship and cooperation!

2026-02-12

What if, 2,000 years ago in Egypt, they had used thin films to wrap mummies? The preservation effect would have been nothing short of divine!

If we were to rewind the timeline to 2000 B.C. along the banks of the Nile, and imagine that ancient Egyptian artisans—not armed with linen but instead equipped with modern membrane technology—had wrapped mummies in thin films, what would happen? This seemingly absurd thought experiment is, in fact, a “collision of embalming and packaging technologies” spanning three millennia.

2026-02-07

Beware! The health minefield of reusing plastic bottles: Different materials make a huge difference—absolutely avoid these behaviors!

The safety of plastic bottles hinges on the material indicated by the "numerical code" stamped on their bottoms. Different materials exhibit vastly varying levels of heat resistance and stability, and they are suited to entirely different applications. In this article, we’ll break down the characteristics of plastic bottles made from various materials, highlight unhealthy practices associated with repeated use, and teach you how to use plastic bottles safely and scientifically.

2026-02-06

Beware when using bean-puzzle stress-relief toys! There’s hidden danger in the materials, and heating them poses risks—these health tips are a must-read!

Recently, "bean-puzzle" crafts have become a new DIY craze among young people, thanks to their immersive creative experience and stress-relieving qualities. However, this trend has also sparked a growing number of controversies: “What materials are bean-puzzles made of?” “Do they contain formaldehyde?” “Is the odor produced when heated harmful to health?”