17

2025

-

09

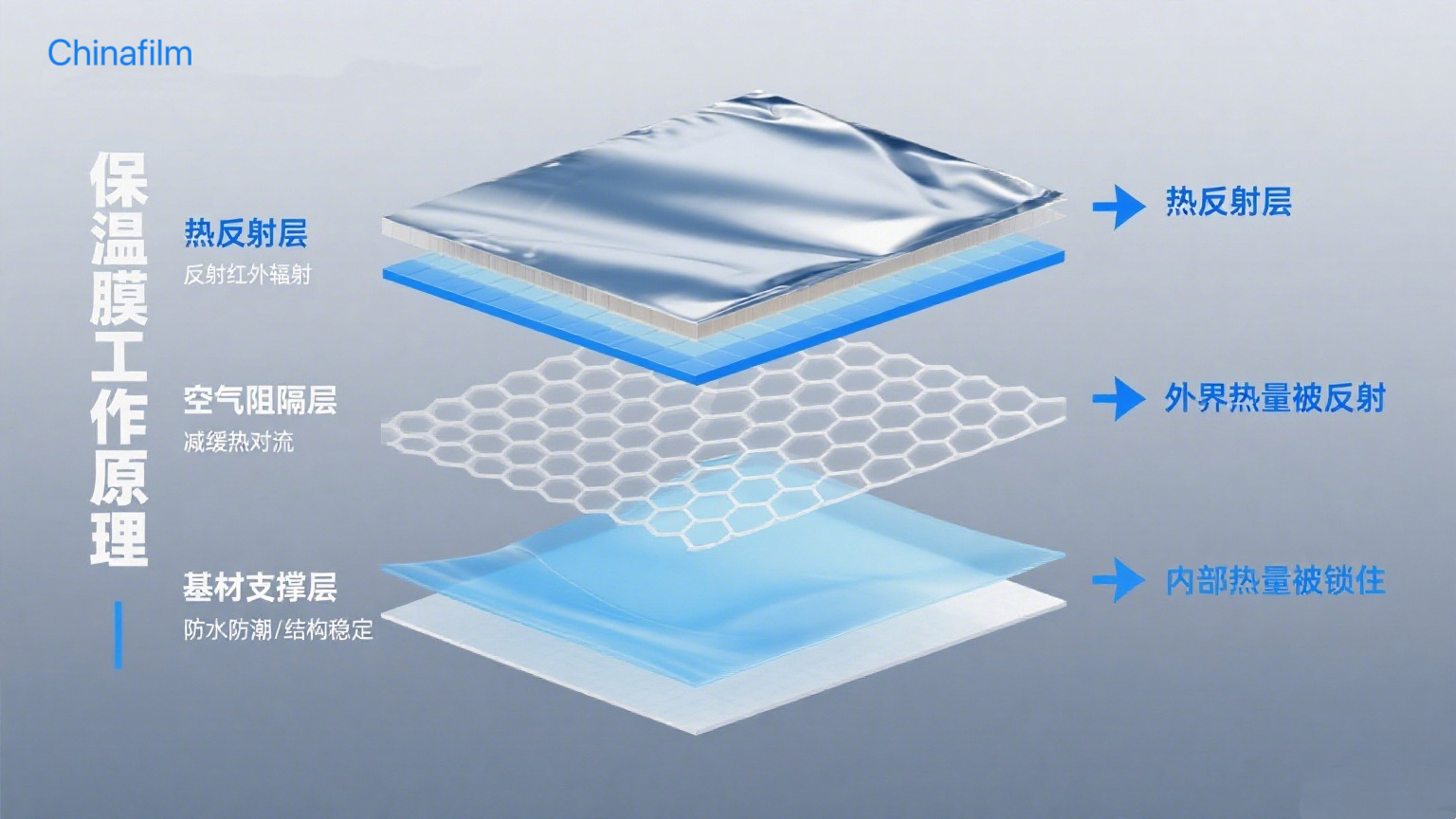

Unveiling the Mystery: Why Does a Single Layer of Film Provide Insulation? A Complete Breakdown of How Insulating Films Work

Author:

Chinafilm Group

In winter, applying a thin film to windows can significantly reduce heat loss, while wrapping takeaway food containers with the same film helps keep meals warm for much longer. Even in agricultural greenhouses, covering the structure with this film can boost the internal temperature by several degrees—steadily and effectively. In these everyday scenarios, what initially seems like a simple, lightweight insulation film actually delivers far more impressive thermal performance than expected. But what exactly is the science behind this "temperature-locking magic"? Today, we’ll break down how insulation films work—from a scientific perspective.

1. First, let’s understand: How does heat "escape"?

To understand the principle of insulation film, you must first grasp the three primary modes of heat transfer—these are precisely the core issues that insulation film is designed to address.

Methods of heat transfer | Transmission characteristics | Typical scenes in everyday life |

Thermal Conduction | Heat is transferred through direct contact between solids, liquids, and gases, flowing from the high-temperature end to the low-temperature end. | Touching the cold metal cup makes your hand feel cooler (heat is conducted from your hand to the cup). |

Thermal Convection | Heat is transferred through the flow of a fluid (liquid or gas), creating circulating convection. | Turn on the kettle, and steam rises upward as cooler air from the surroundings rushes in to replace it (convection causes heat to spread). |

Thermal radiation | Heat is transferred in the form of electromagnetic waves, requiring no medium and able to occur even in a vacuum. | When sunlight shines on your body, it feels warm (the sun transfers heat through thermal radiation). |

The core function of insulation film is to "block" all three modes of heat transfer simultaneously—thanks to its unique structure and material properties—thereby minimizing heat loss and achieving an effective insulation effect.

II. The "Temperature-Keeping Secret" of Insulation Film: Four Core Working Principles

(1) Principle 1: Isolate from air, blocking thermal convection

- Key logic: Airflow is the primary carrier of thermal convection. The insulation film reduces air movement by creating a "sealed air layer," thereby minimizing heat loss caused by thermal convection.

- Specific implementation:

- The insulation film itself has excellent sealing properties; when applied to the surface of objects (such as windows or food containers), it creates a thin layer of air between the film and the object.

- Some porous insulation films (such as bubble insulation) enclose countless tiny air bubbles inside, and these bubbles are completely independent of each other, preventing any convective circulation from occurring.

- Effectiveness data: Enclosed air layers can reduce heat loss caused by convection by approximately 40% to 60%, making them one of the most fundamental and critical insulation mechanisms in thermal insulation films.

(II) Principle 2: Low-thermal-conductivity material to minimize heat transfer

- Core premise: Different materials have varying thermal conductivity coefficients—lower coefficients mean heat is more difficult to transfer through the material.

- Material selection for insulation film:

- Mainstream insulation films commonly use polymer materials such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC), which have extremely low thermal conductivity—approximately 0.03 to 0.05 W/(m·K)—far lower than that of metals (e.g., iron, with a thermal conductivity of about 45 W/(m·K)).

- Some high-end insulation films incorporate filler materials such as glass fibers and aerogels, further reducing the overall thermal conductivity and enhancing their ability to block heat transfer.

- Practical function: When heat attempts to conduct through the path of "object – insulation film – external environment," the low-thermal-conductivity material acts like a "barrier," slowing down the rate of heat transfer and preventing rapid heat loss.

(III) Principle 3: Reflective Layer Design to Resist Thermal Radiation

- Addressing the issue: Thermal radiation can travel without a medium, and ordinary films cannot directly block it. Therefore, some insulation films incorporate an "reflective layer" to bounce back the thermal radiation.

- How the reflective layer is implemented:

- Coating the surface of the thin film with an ultra-thin metal layer (such as an aluminum film), which boasts an reflectivity of over 80%—effectively reflecting most thermal radiation back into the insulated area;

- Some non-aluminized insulation films are processed using special techniques to create a highly reflective surface structure, which can also help reflect thermal radiation effectively.

- Typical scenario:

- The thermal insulation film used in agricultural greenhouses works by reducing heat loss from inside the shed to the outside through its reflective layer during the day, while retaining the heat stored inside overnight.

- The silver insulation film lining the inside of the takeout保温 bag reflects the food's own thermal radiation, slowing down the rate at which the meal cools down.

(4) Principle 4: Seal tightly to prevent moisture and minimize additional heat loss.

- An often-overlooked point: The presence of moisture—in liquid or gaseous form—can significantly accelerate heat transfer (water has a thermal conductivity of about 0.6 W/(m·K), far higher than that of air). Therefore, the "moisture resistance" of insulation films also plays an important supporting role in enhancing thermal performance.

- The moisture-proof mechanism of insulation film:

- The polymer film itself possesses excellent water resistance, effectively preventing external moisture from penetrating into the insulation area and avoiding accelerated heat transfer caused by moisture.

- Some insulation films are equipped with moisture-proof coatings (such as polyvinylidene chloride, or PVDC, coatings) to further enhance their moisture-resistant performance, making them particularly suitable for humid environments like kitchens, bathrooms, and agricultural greenhouses.

- Practical impact: Moisture-proof design reduces additional heat loss caused by moisture, leading to more stable insulation performance and extending the insulation duration by approximately 15%–20%.

III. Principle Differences Among Different Types of Insulation Films: Targeted Optimization

Insulation films on the market are not "one-size-fits-all"; instead, they are specifically enhanced based on application scenarios according to the principles mentioned above, forming different types of products.

Types of Insulation Films | Core Material / Structure | Key Reinforced Principles | Applicable Scenarios |

Ordinary PE Insulation Film | Single or multilayer polyethylene film | Air barrier (thermal convection), low thermal conductivity (heat conduction) | Home window insulation, temporary food covering (e.g., leftovers) |

Bubble Insulation Film | Double-layer film + internal independent bubbles | Enhanced closed air layer (blocks thermal convection), low thermal conductivity | Insulation for express packages (e.g., fresh food, medicine), moisture-proof and insulation for furniture transport |

Aluminum-coated Reflective Insulation Film | Film + surface aluminum layer | Reflects thermal radiation, air barrier, low thermal conductivity | Agricultural greenhouses, takeout insulation bags, car sunshade insulation |

Composite Insulation Film | Multilayer structure (e.g., PE + non-woven fabric + aluminum film) | Simultaneously blocks heat conduction, convection, and radiation, also moisture-proof | Building exterior wall insulation, cold chain transportation (e.g., vaccines, frozen food) |

4. Applications of Insulation Films in Daily Life: Practical Implementation of Principles

(1) Home Scenarios: Small Films Solve Big Problems

- Window Insulation:

- When applying window insulation film, clean the window glass thoroughly to ensure a sealed air layer between the film and the glass;

- Principle application: Blocks thermal convection through the sealed air layer, low thermal conductivity material reduces heat conduction, some aluminum-coated films can also reflect indoor thermal radiation;

- Effect: Can raise indoor temperature by 3-5°C in winter, reducing heating energy consumption by about 20%.

- Food Insulation:

- When covering leftovers with insulation film, it should be tightly attached to the surface of the plate to avoid leaving a large amount of air between the film and the food (to prevent heat loss caused by air convection);

- Principle application: Low thermal conductivity material reduces heat conduction, sealing blocks thermal convection;

- Note: When heating food with film, remove the insulation film first to avoid deformation of the film or release of harmful substances due to high temperature.

(2) Agricultural Scenarios: Insulation Films Aid Crop Growth

- Greenhouse Insulation Film:

- Choose aluminum-coated reflective insulation film, allowing sunlight (shortwave radiation) to enter the greenhouse during the day to heat the air and soil;

- At night when the temperature inside the greenhouse drops, the reflective layer reflects the long-wave thermal radiation of objects inside back into the greenhouse, while the sealed air layer blocks thermal convection;

- Additional effects: Moisture resistance can reduce humidity fluctuations inside the greenhouse, preventing crops from getting sick due to dampness; low thermal conductivity material stabilizes the temperature inside, reducing the impact of day-night temperature differences on crops.

(3) Logistics Scenarios: Ensuring "Temperature Safety" of Goods

- Fresh Food Express:

- Commonly use bubble insulation film combined with ice packs; the bubble film's sealed air layer blocks thermal convection, and low thermal conductivity material slows external heat transfer;

- For transporting fresh food to high-temperature areas, aluminum-coated insulation film is additionally used to reflect external sunlight's thermal radiation, further delaying ice pack melting;

- Medicine Transportation:

- For medicines requiring low-temperature storage (e.g., insulin), composite insulation film packaging is used, with multilayer structures blocking all three heat transfer methods simultaneously;

- Principle application: By comprehensively blocking heat transfer, it ensures medicines remain within the specified temperature range (usually 2-8°C) during transportation.

5. Conclusion

Seemingly simple insulation films are based on precise application of heat transfer principles — through the four core mechanisms of "blocking heat conduction, isolating thermal convection, reflecting thermal radiation, and sealing moisture," a single film achieves efficient insulation. From home windows to agricultural greenhouses, from fresh food express to medicine transportation, the application scenarios of insulation films continue to expand, essentially meeting the demand for "heat control."

With technological development, future insulation films may upgrade towards "lighter, higher insulation efficiency, and biodegradable" directions, such as using bio-based polymer materials to replace traditional plastics, reducing environmental burden while retaining insulation performance. Regardless of form changes, their core working principle always revolves around "blocking heat transfer" — understanding this allows us to choose and use insulation films more scientifically, enabling them to better serve life and production.

Insulation Film,Principle

Latest News

2026-02-17

Chinafilm Group: Embarking on a New Journey with Practical Action, Building a Brilliant Chapter with Our Original Aspirations.

With the Golden Horse raising its head and ushering in a new era, all things are renewed and a splendid chapter is written. On this occasion of the Spring Festival in the Year of the Fire Horse (Bingwu), all colleagues at Chinafilm Group extend our warmest New Year greetings to our clients, partners, and friends from all walks of life who have silently supported us throughout the years—thank you for your enduring companionship and cooperation!

2026-02-12

What if, 2,000 years ago in Egypt, they had used thin films to wrap mummies? The preservation effect would have been nothing short of divine!

If we were to rewind the timeline to 2000 B.C. along the banks of the Nile, and imagine that ancient Egyptian artisans—not armed with linen but instead equipped with modern membrane technology—had wrapped mummies in thin films, what would happen? This seemingly absurd thought experiment is, in fact, a “collision of embalming and packaging technologies” spanning three millennia.

2026-02-07

Beware! The health minefield of reusing plastic bottles: Different materials make a huge difference—absolutely avoid these behaviors!

The safety of plastic bottles hinges on the material indicated by the "numerical code" stamped on their bottoms. Different materials exhibit vastly varying levels of heat resistance and stability, and they are suited to entirely different applications. In this article, we’ll break down the characteristics of plastic bottles made from various materials, highlight unhealthy practices associated with repeated use, and teach you how to use plastic bottles safely and scientifically.

2026-02-06

Beware when using bean-puzzle stress-relief toys! There’s hidden danger in the materials, and heating them poses risks—these health tips are a must-read!

Recently, "bean-puzzle" crafts have become a new DIY craze among young people, thanks to their immersive creative experience and stress-relieving qualities. However, this trend has also sparked a growing number of controversies: “What materials are bean-puzzles made of?” “Do they contain formaldehyde?” “Is the odor produced when heated harmful to health?”