11

2025

-

10

Photo Album Printing: Pre-coated Film vs. Lamination—Balancing Cost and Quality

Author:

Chinafilm Group

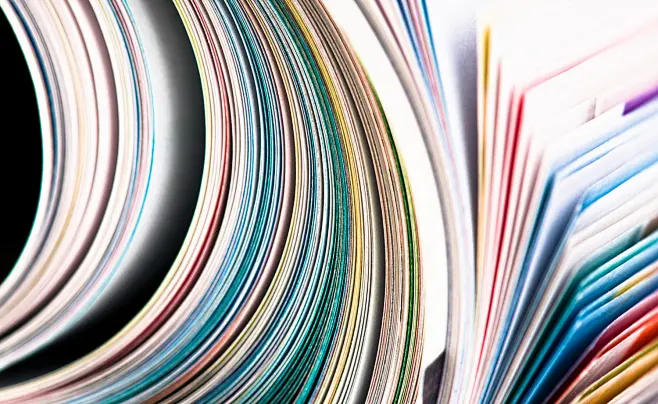

Foreword: Lamination Adds Charm to the Photo Album

In the world of brochure printing, lamination is like a magical makeup artist, instantly transforming brochures into something fresh and vibrant. Not only does it enhance the visual appeal of the brochure, making colors more vivid and adding a brilliant sheen, but it also significantly boosts the durability of the material—providing protection against water, stains, and abrasion. Among the various lamination methods available, pre-coated film and liquid coating have garnered considerable attention, each offering unique advantages and characteristics. Today, we’ll dive deeper into the decision-making process: how to choose between pre-coated film and liquid coating for brochure printing, striking the perfect balance between cost-effectiveness and desired outcomes.

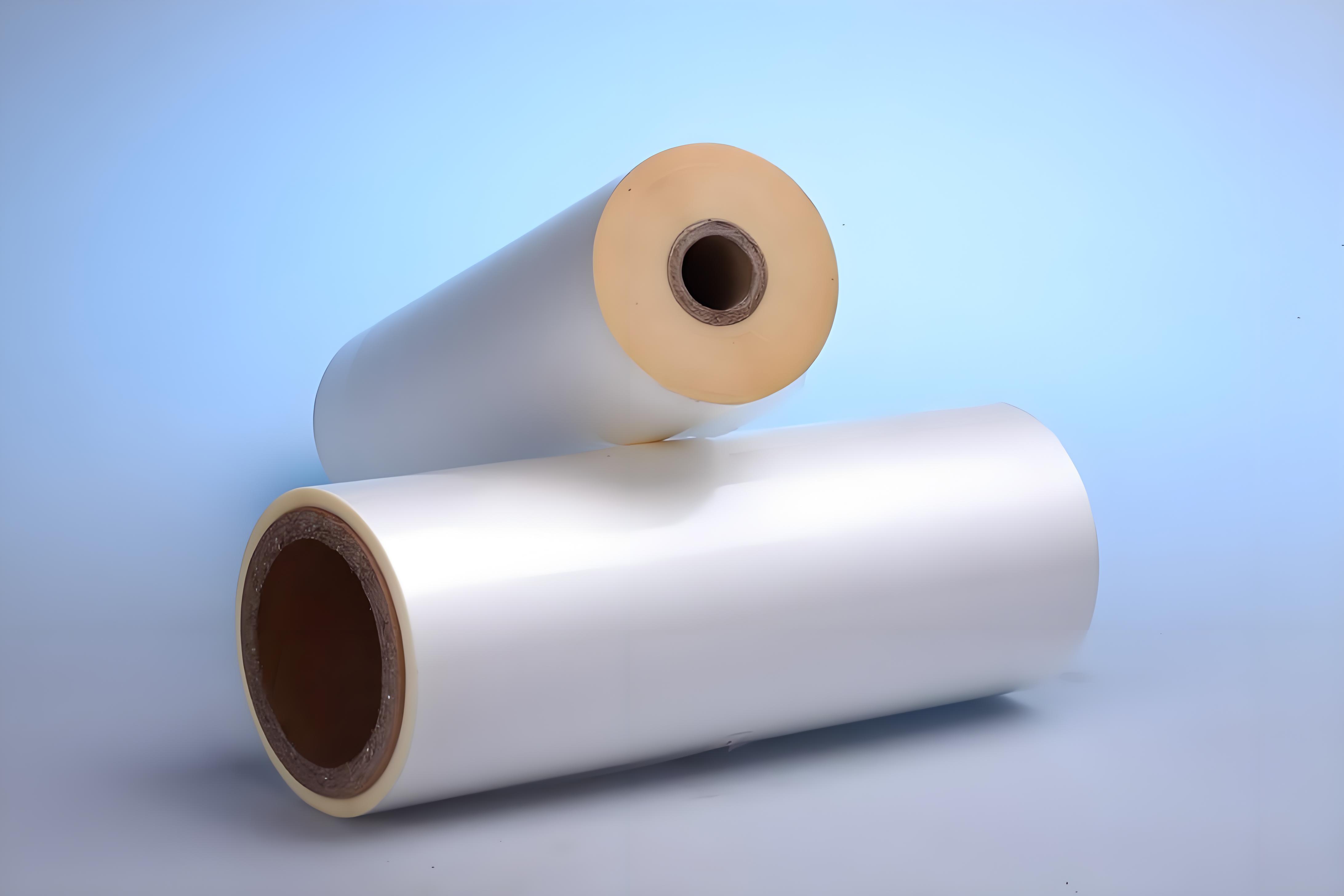

I. Pre-coated Film: A Symbol of Convenience and Quality

(1) Process Principle

Pre-coated film—its name itself reveals its unique feature. This process involves pre-applying adhesive to plastic films, rolling them up, and then laminating them onto printed paper materials. These pre-glued films are supplied by specialized manufacturers; when you're ready to use them, simply heat-press the coated film together with your printed brochure sheets, completing the lamination process effortlessly. It’s just like using instant food products that come with pre-prepared sauces—you can cook them right away, without needing to go through any complicated mixing or preparation steps.

(II) Performance Advantages

- High-quality fit : During the hot-pressing process, the pre-coated film adheres tightly to the album paper, effectively preventing issues like wrinkles or bubbles. This ensures that the laminated album boasts a perfectly smooth and glossy surface—delivering exceptional visual appeal as well as a luxurious tactile experience, significantly enhancing the overall quality and sophistication of the album. Just imagine holding a beautifully mirror-like album in your hands; wouldn’t it feel truly exquisite?

- Excellent environmental performance : Using pre-coated film for lamination avoids the pollution issues, such as organic solvent emissions, that can arise with some traditional lamination processes. The EVA hot-melt adhesive used in this method is both environmentally friendly and gentle on human health, making it especially suitable for eco-friendly printing applications like food packaging boxes and children’s books—products that demand high environmental standards. When parents choose to print picture books for their kids, they can feel much more confident knowing this lamination method prioritizes sustainability and safety.

- Adaptable to多种paper Whether it's paper with a smooth surface or relatively rough, uneven paper, the pre-coated film demonstrates excellent adhesion performance and boasts a wide range of applicability. This means that when choosing art book paper, you have more flexibility—and won’t need to worry too much about compatibility issues between the paper and the lamination process.

(III) Cost Considerations

- Material Cost : Since pre-coated film has undergone pre-coating processing, its manufacturing cost is relatively high, which also results in a higher material price compared to some common laminating materials. When printing photo albums in bulk, the increase in material costs becomes particularly noticeable.

- Equipment cost While pre-coated film laminating equipment is relatively compact, affordable, and easy to operate, purchasing the equipment still requires a certain financial investment if you haven’t had such machinery before. However, in the long run, its ease of operation and higher production efficiency can help offset the initial equipment costs to some extent.

- Total Cost Considering that pre-coated film can reduce defect rates and boost production efficiency, in some album printing projects with high-quality requirements and large print runs, the overall cost may not be much higher than other lamination methods. Moreover, its superior lamination quality can enhance the added value of the album, making it, from a holistic profitability perspective, sometimes the more cost-effective choice after all.

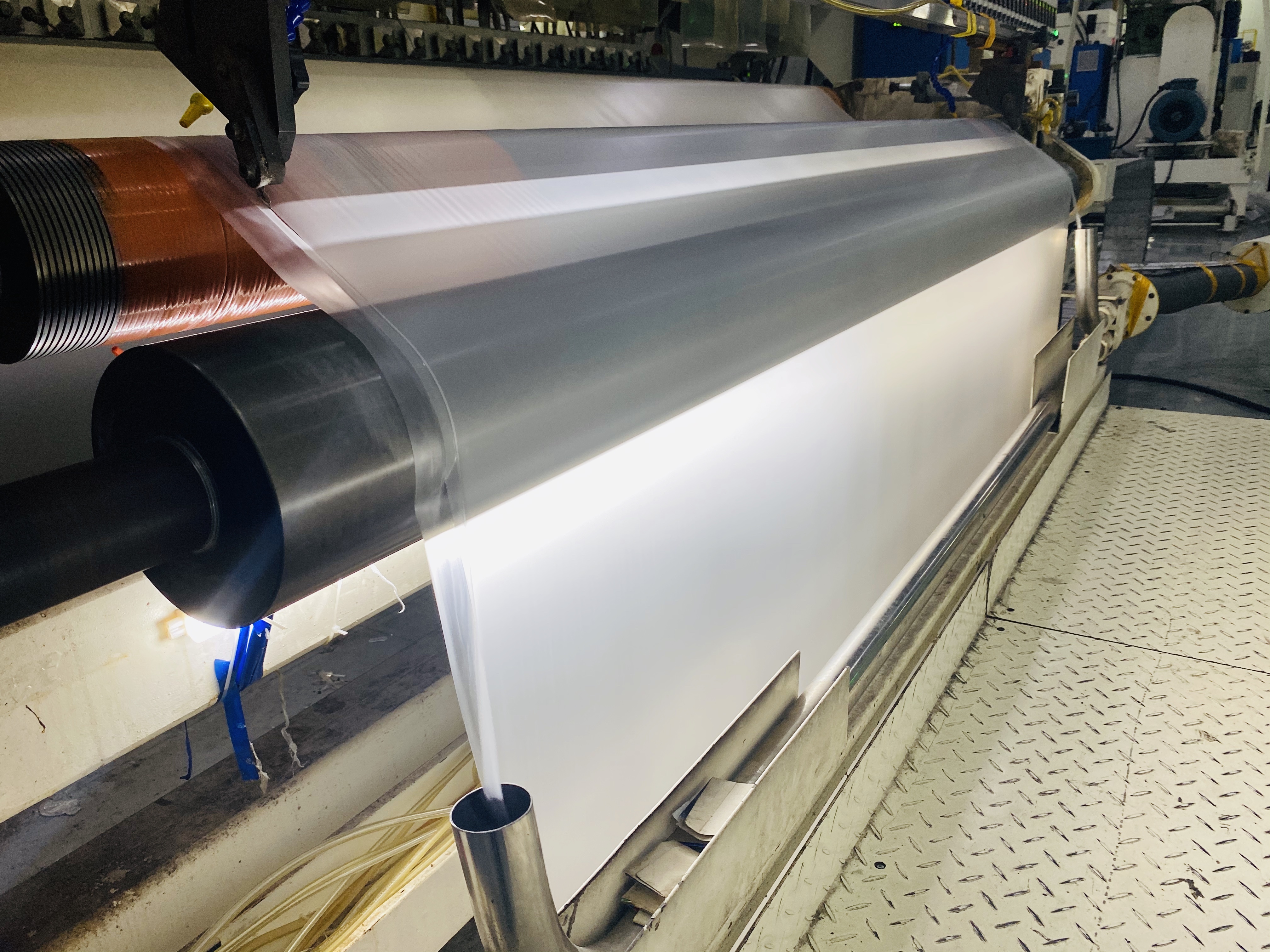

II. Lamination: The Darling of Cost and Efficiency

(1) Process Principle

Laminating involves evenly applying a specialized liquid onto the surface of printed paper, followed by a curing process. This procedure requires the use of a dedicated laminating machine—essentially "dressing" the album paper with a protective "suit" made from the special liquid. Once cured, this "protective suit" adheres firmly to the paper's surface, providing both protection and an attractive decorative finish.

(II) Performance Advantages

- High Adhesion Strength : The lamination has exceptionally strong adhesion, ensuring that the film adheres tightly to the album paper and minimizing the risk of delamination. At the same time, it boasts excellent sealing performance, effectively preventing moisture, dust, and other external elements from compromising the album, thus providing reliable protection for your cherished keepsakes.

- Excellent surface effect : After lamination, the surface of the photo album resembles a mirror, boasting exceptionally high gloss—whether it’s a glossy or matte finish, both deliver a distinct tactile quality. Glossy lamination makes the album’s colors pop with vibrant brilliance, while matte lamination imparts a subtle yet luxurious elegance, elevating the album’s overall sophistication and premium appeal.

(III) Cost Considerations

- Material Cost : The specialized liquid material used for lamination is relatively low in cost, and during application, it can even be appropriately diluted based on actual needs, further reducing expenses. For instance, one kilogram of lamination liquid can cover a large area, resulting in an actual cost of less than one yuan per square meter—clearly offering a significant advantage in terms of cost-effectiveness.

- Equipment cost : The price of laminating machines varies depending on their type and specifications. Generally speaking, some smaller laminating machines are relatively affordable. However, it’s important to note that larger laminating machines come with a higher price tag and occupy a considerable amount of space, requiring a dedicated operational area—this, to some extent, increases the equipment’s overall cost.

- Labor costs : Laminating is relatively simple to operate, and once laminated, there’s minimal post-processing required—no need for complex cutting or other intricate procedures, which helps save considerable labor costs. In today’s environment of steadily rising labor expenses, this is undoubtedly a major advantage of laminating. This cost-saving benefit becomes even more pronounced, especially when producing photo albums in high-volume batches.

III. The Art of Balancing Cost and Effectiveness

(1) Quality requirements determine the choice of effectiveness

- High-end Photo Album "If you're printing high-end art albums, collector’s editions, or other products with exceptionally high quality demands, pre-coated film may be the better choice. Its outstanding adhesion and eco-friendly properties perfectly highlight the exquisite content of the album, enhancing its collectible value and artistic appeal. For instance, a renowned painter’s collection, when laminated with pre-coated film, can better preserve the intricate details of the artwork, allowing readers to fully appreciate the artist’s creative brilliance."

- Standard promotional brochure For general corporate brochures, product catalogs, and similar materials, the lamination effect already meets the requirements. Its high adhesion strength and outstanding surface finish ensure that the brochures present a professional image during promotional activities, while the relatively low cost helps keep printing budgets in check. For instance, a fast-moving consumer goods company can use lamination for its product brochures, guaranteeing both aesthetic appeal and cost-effectiveness even when printing on a large scale.

(II) Budget Constraints Influence Cost Decisions

- Adequate budget "When your budget is relatively ample, consider prioritizing pre-coated film. Although the material and equipment costs are relatively high, it delivers superior lamination quality. In the long run, this approach positively impacts brand image enhancement and helps increase product added value. For instance, a premium-brand company opted for pre-coated film in its brochure printing to underscore its high-end positioning—despite the higher cost, it perfectly aligns with the brand’s sophisticated image."

- Limited budget "If your budget is tight, laminating is a highly cost-effective option. With its low material and labor costs, it allows you to maximize control over printing expenses while still delivering satisfactory lamination results. For small businesses or projects with limited budgets, laminating is an economical and practical choice for meeting brochure-printing needs. For instance, a startup’s promotional brochure—when faced with financial constraints—can rely on the laminating process to fulfill basic printing requirements without placing excessive financial strain on the company."

(III) Production Scale Affects Overall Costs

- Mass production When producing photo albums in bulk, the advantages of lamination become even more pronounced. It’s simple to operate, highly efficient, and allows for the rapid laminating of large quantities of albums. Moreover, as production scales up, the low cost of lamination materials further helps reduce the unit cost. For instance, if a publisher needs to print a large number of instructional material–supplemented albums, using the lamination process can efficiently complete the laminating task in a short time while also keeping costs down.

- Small-batch production For small-batch brochure printing, the flexibility of pre-coated film and the ease of equipment operation truly shine. Pre-coated film laminating machines can be turned on and off as needed, offering great production flexibility—allowing even small-volume prints to be completed efficiently without unnecessary downtime. This also prevents excessive cost waste caused by equipment idleness. For instance, a design studio recently customized a limited number of creative brochures for a client, and with the help of a pre-coated film laminating machine, they were able to effortlessly finish the lamination process.

Conclusion: Make informed choices

In brochure printing, both pre-coated film and lamination have their own advantages and disadvantages, offering distinct characteristics in terms of cost and visual impact. By analyzing various factors—such as the underlying process principles, the resulting aesthetic benefits, and cost considerations—we can carefully weigh these elements against each other, ultimately making the most suitable choice based on your brochure’s quality requirements, budget constraints, and production scale. Whether you prioritize the premium quality of pre-coated film or focus on cost-effectiveness with lamination, both methods bring unique value to brochure printing, ensuring your printed materials shine brightly in the market. We hope this article helps clarify your decision-making process when selecting the right lamination technique for your brochures, enabling you to effortlessly create stunning, high-quality print pieces that meet your expectations.

Latest News

2026-02-26

Don't use plastic bags carelessly! Here are 4 tips to spot the trickery in the innermost layer material in just 5 seconds.

Supermarket shopping bags, takeout bags, snack bags, and the like have long been integrated into daily life. Most plastic bags feature a multi-layer composite structure, and the material of the innermost layer directly determines their safety, food-contact suitability, and intended use scenarios.

2026-02-17

Chinafilm Group: Embarking on a New Journey with Practical Action, Building a Brilliant Chapter with Our Original Aspirations.

With the Golden Horse raising its head and ushering in a new era, all things are renewed and a splendid chapter is written. On this occasion of the Spring Festival in the Year of the Fire Horse (Bingwu), all colleagues at Chinafilm Group extend our warmest New Year greetings to our clients, partners, and friends from all walks of life who have silently supported us throughout the years—thank you for your enduring companionship and cooperation!

2026-02-12

What if, 2,000 years ago in Egypt, they had used thin films to wrap mummies? The preservation effect would have been nothing short of divine!

If we were to rewind the timeline to 2000 B.C. along the banks of the Nile, and imagine that ancient Egyptian artisans—not armed with linen but instead equipped with modern membrane technology—had wrapped mummies in thin films, what would happen? This seemingly absurd thought experiment is, in fact, a “collision of embalming and packaging technologies” spanning three millennia.

2026-02-07

Beware! The health minefield of reusing plastic bottles: Different materials make a huge difference—absolutely avoid these behaviors!

The safety of plastic bottles hinges on the material indicated by the "numerical code" stamped on their bottoms. Different materials exhibit vastly varying levels of heat resistance and stability, and they are suited to entirely different applications. In this article, we’ll break down the characteristics of plastic bottles made from various materials, highlight unhealthy practices associated with repeated use, and teach you how to use plastic bottles safely and scientifically.

2026-02-06

Beware when using bean-puzzle stress-relief toys! There’s hidden danger in the materials, and heating them poses risks—these health tips are a must-read!

Recently, "bean-puzzle" crafts have become a new DIY craze among young people, thanks to their immersive creative experience and stress-relieving qualities. However, this trend has also sparked a growing number of controversies: “What materials are bean-puzzles made of?” “Do they contain formaldehyde?” “Is the odor produced when heated harmful to health?”