15

2025

-

10

Pre-coated film waste rate control: Proper storage methods reduce waste by 5%.

Author:

Chinafilm Group

Preface

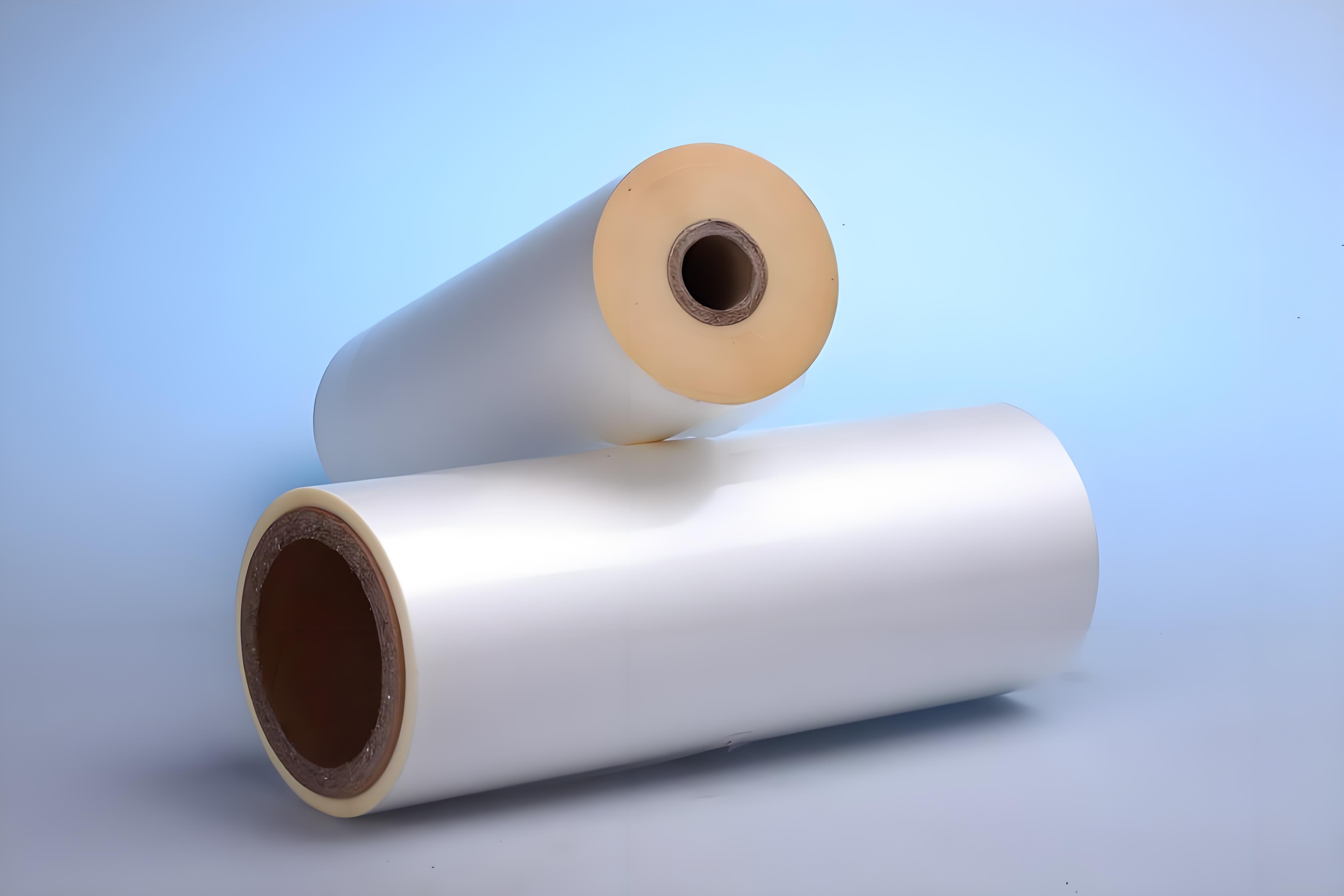

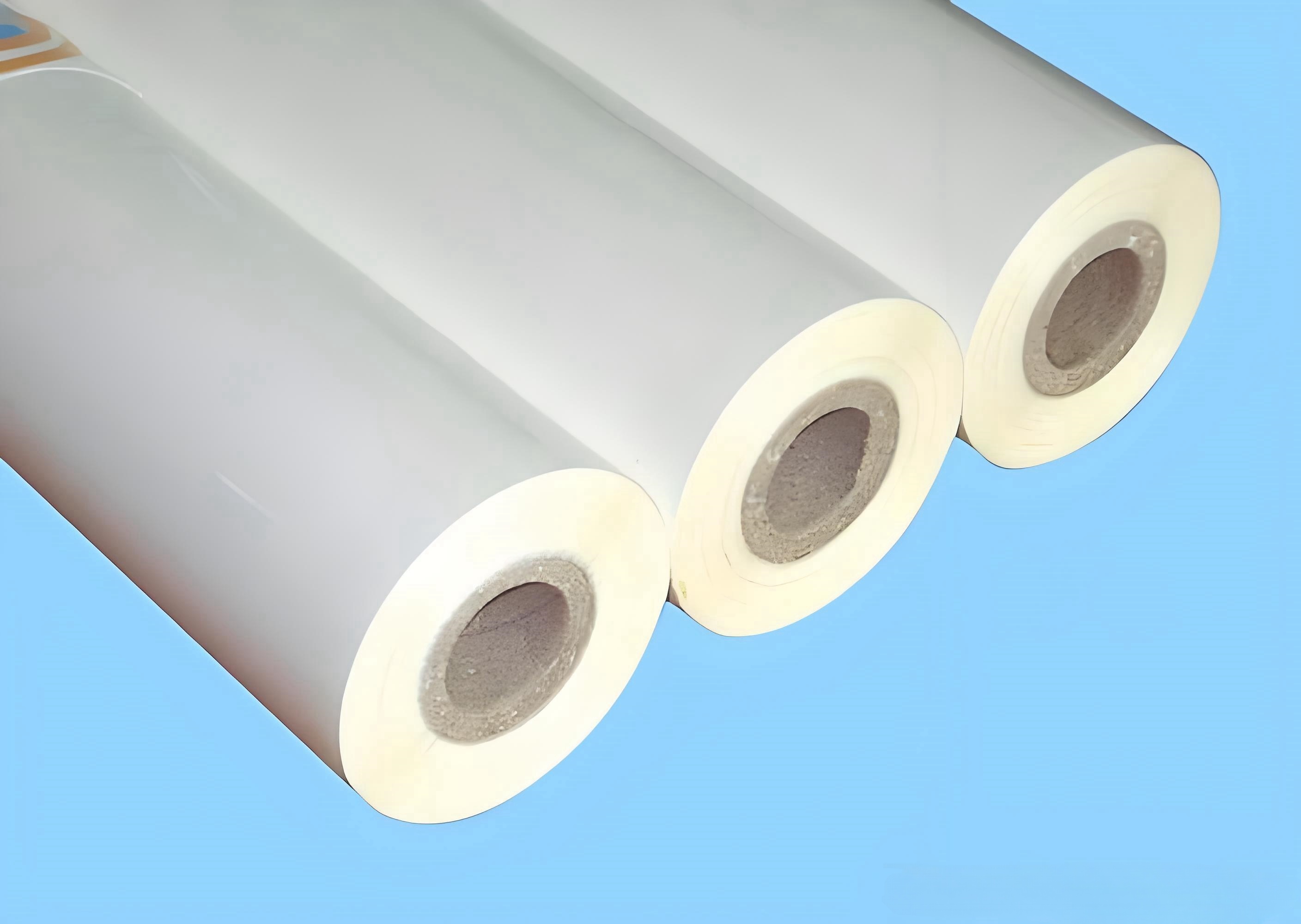

In industries such as packaging and printing, pre-coated film is an indispensable and vital material. It effectively enhances the gloss, abrasion resistance, and water repellency of product surfaces, ensuring top-notch product quality. However, during daily use, the issue of film wastage continues to pose significant challenges for many companies. According to industry statistics, improper storage practices often lead to problems like wrinkling, adhesion, and aging of the pre-coated film, resulting in substantial waste—and in some cases, the average loss rate can even reach… 8%-12% 。

But in reality, as long as you master the correct storage method, you can significantly reduce the loss of pre-coated film. Extensive practical experience has proven that a scientifically sound and reasonable storage approach can lower the pre-coated film's wastage rate. 5% This data is of significant importance for businesses in controlling costs and enhancing efficiency. In this article, we will thoroughly explain how to manage and minimize pre-coated film loss during storage—covering common causes of film wastage, specific guidelines for proper storage methods, as well as strategies for monitoring and optimizing the loss rate.

I. Common Causes and Impacts of Pre-Coated Film Loss

(1) Common Causes of Loss

- Environmental temperature and humidity are unsuitable: Excessively high temperatures can soften the adhesive layer of the pre-coated film, causing the rolls to stick together; conversely, excessively low temperatures make the pre-coated film brittle and prone to cracking. When humidity is too high, the pre-coated film easily absorbs moisture, leading to condensation on its surface and compromising the performance of subsequent applications.

- Improper stacking of storage: Randomly stacking pre-coated films or piling them too high can place excessive pressure on the underlying rolls, leading to deformation and wrinkling—and in severe cases, even compromising the structure of the pre-coated film itself.

- Effects of Light and Oxygen: Prolonged exposure to direct sunlight or intense lighting can accelerate the aging of the pre-coated film, leading to issues such as discoloration and reduced performance. Meanwhile, oxygen can also react with the components in the pre-coated film, causing it to deteriorate over time.

- Improper storage containers: Using containers that are not breathable or moisture-proof to store pre-coated films can increase humidity inside the container and fail to effectively block external contaminants, making the pre-coated films prone to contamination.

(II) The Impact of LossesModule

- Increasing business costs: The damaged pre-coated film cannot be used as intended, forcing the company to repurchase it—undoubtedly raising raw material expenses. Meanwhile, disposing of the discarded pre-coated film also incurs significant labor and material costs.

- Impact on production schedule: When the consumption of pre-coated film is significant, leading to insufficient inventory, it forces production to halt, delays delivery times, and ultimately harms the company’s reputation and customer satisfaction.

- Reducing product quality: If slightly damaged pre-coated films are forced into use, they can compromise the product’s appearance and performance—leading to issues such as uneven coatings and reduced adhesion—thereby diminishing the product’s market competitiveness.

II. Proper Storage Methods: Reduce 5% The Key to Loss

(1) Control the temperature and humidity of the storage environment

- Temperature Control: Maintain the storage environment's temperature at 15°C–25°C Between them, temperature gauges can be installed inside the warehouse to monitor temperature changes in real time. When temperatures rise too high during summer, air conditioning or ventilation systems can be activated to cool down the space; and when temperatures drop too low in winter, appropriate heating measures can be taken—though care should be taken to prevent the pre-coated film from coming into direct contact with heat sources.

- Humidity Control: The relative humidity of the storage environment should be maintained at 40%-60% Moisture levels can be monitored using a hygrometer. If humidity is too high, a dehumidifier can be used to reduce moisture; if it’s too low, lightly misting the area or using a humidifier can help adjust the conditions—just be sure to avoid water pooling on the floor to prevent the pre-coated film from getting damp.

(II) Standardize the Stacking Method of Pre-coated Films

- Stacking height: Adjust the stacking height appropriately based on the specifications and weight of the pre-coated film. Generally, the coil diameter is 500mm The following, stack height does not exceed 3 Layer; diameter within 500mm The above, with a stacking height not exceeding 2 Layer, preventing the underlying membrane from deforming due to excessive pressure.

- Stacking Support: When stacking pre-coated films, place wooden or plastic pallets between each layer to provide even support and ensure uniform pressure on the rolls. At the same time, make sure the pallets remain flat and dry, and avoid using sharp objects that could scratch the pre-coated film.

- Avoid tilting: When stacking pre-coated films, ensure they are neatly aligned and kept vertical to prevent any tilting, which could cause the rolls to slip or deform.

(III) Isolate from Light and Oxygen

- Store away from light: Keep the pre-coated film in a cool, dark warehouse to prevent direct sunlight or intense illumination. Install shade curtains on the warehouse windows to minimize light entry. If using pre-coated film packaged in transparent materials, cover the exterior of the packaging with a light-blocking cloth to provide an additional layer of protection against light.

- Sealed storage: For pre-coated films that have not been fully used, promptly seal the packaging to prevent oxygen from entering. You can tightly wrap the rolls with sealing film or place them in a plastic container with excellent sealing performance. Additionally, regularly check the integrity of the seal; if any damage is detected, reseal immediately to maintain protection.

(4) Selecting the Right Storage Containers and Location

- Storage container selection: Prioritize breathable, moisture-resistant containers, such as plastic or wooden boxes with ventilation holes. Avoid using containers that are overly airtight and non-breathable, as this can lead to increased humidity inside the container.

- Storage Location Selection: Store the pre-coated film in a dry, well-ventilated area of the warehouse, away from water sources, heat sources, and corrosive materials. Additionally, avoid placing the pre-coated film near warehouse doors or passageways to prevent damage caused by collisions with people or vehicles.

III. Key Points for Daily Management of Pre-Coated Film Storage

(1) Establish a Storage Management System

- Clearly define responsibility allocation: Assign dedicated warehouse managers to oversee the storage and management of pre-coated films, clearly outlining their duties, which include environmental monitoring, stacking and organization, as well as inventory checks.

- Develop operational guidelines: Prepare a pre-coated film storage operation manual that clearly outlines storage environment requirements, stacking methods, retrieval procedures, and other relevant details, ensuring that management personnel follow the established protocols.

- Regular Training: Regularly train warehouse managers to familiarize them with the properties and storage requirements of pre-coated films, ensuring they master proper storage methods and emergency response measures.

(2) Properly Conduct Inventory Counting and Inspection

- Regular Inventory Check: Conduct an inventory of the pre-coated film stock once a week, verifying quantities, specifications, and other relevant details to ensure the accuracy of inventory data. At the same time, promptly remove expired or damaged pre-coated films to prevent unnecessary占用 of storage space.

- Daily Inspection: Conduct daily checks on the storage environment’s temperature and humidity, the stacking condition of pre-coated films, the sealing integrity of packaging, and other relevant factors. Address any issues promptly upon detection. For instance, if temperature or humidity levels exceed the standard, adjust them immediately; if film stacks are leaning, realign them right away; and if packaging is damaged, seal it promptly or replace it with new packaging.

(III) Standardize the Pre-coated Film Retrieval Process

- First-in, first-out: According to “ First-In, First-Out ” The principle is to use pre-coated film directly, avoiding long-term storage that could lead to aging and degradation of the film. The date of入库 (entry into the warehouse) should be clearly marked on the pre-coated film packaging for easy identification by management personnel.

- Handle with care: When handling the pre-coated film, lift and place it gently to avoid forceful pulling or collisions, preventing wrinkles, tears, or other damage to the film.

- Return to proper place promptly: After use, if the pre-coated film is not fully utilized, it should be promptly returned to its original location and stored according to the prescribed stacking method and sealing requirements—avoiding随意 placement altogether.

IV. Monitoring and Optimization of Pre-Coated Film Loss Rate

(1) Establish a Loss Rate Monitoring System

- Set a loss rate target: Based on the company's actual production and industry standards, establish a reasonable pre-coated film loss rate target, such as keeping the loss rate below 3% Within.

- Data Collection and Statistics: Daily record the purchase quantity, usage, and waste volume of pre-coated films, and conduct weekly statistical analysis to calculate the actual loss rate, comparing it against the established targets.

- Cause Analysis: If the actual loss rate exceeds the set benchmark, promptly analyze the reasons to determine whether the issue lies in the storage phase, usage phase, or another环节. Then, develop targeted measures to address the problem effectively.

(II) Continuously Optimize Storage Solutions

- Regular Assessment: Conduct a quarterly evaluation of the pre-coated film storage plan, analyzing whether the storage methods and management practices are reasonable and identifying any areas for improvement.

- Drawing on experience: Focus on advanced pre-coated film storage technologies and management practices within the industry, and tailor these insights to your company's specific circumstances to optimize and upgrade your storage solutions.

- Trial Verification: For the improved storage solution, a small-scale trial can be conducted first to monitor changes in the pre-coating film loss rate during the test period. If the trial yields positive results, the solution can then be rolled out and implemented across the entire plant.

Conclusion

Controlling the wastage rate of pre-coated films is a critical step for businesses aiming to reduce costs and improve efficiency, while proper storage methods are key to minimizing film losses. By managing storage environment temperature and humidity, standardizing stacking practices, shielding the films from light and oxygen, and strengthening daily management procedures, companies can effectively lower the wastage rate of pre-coated films. 5% , even reaching lower levels.

Meanwhile, establishing a loss rate monitoring system and continuously optimizing storage solutions will further enhance the management of pre-coated films, providing strong support for the company's stable growth. We hope the methods and key points introduced in this article will serve as a valuable reference for businesses looking to improve their pre-coated film storage and loss control practices, helping companies achieve their goals of cost reduction and efficiency enhancement.

Latest News

2025-12-07

Today is Great Snow—The Middle Membrane is here with you, helping you ward off the chill of winter.

2025-12-05

The “Invisible Assistant” of 3D Printing: How Thin-Film Materials Are Rewriting the Rules of Printing?

This article unveils the “cross-border collaboration” between thin films and 3D printing: From platform protection to functional carriers—what secrets do thin films hold? And what technological breakthroughs will they drive?

2025-12-04

The “core equipment” for thin-film production: From particles to finished products, these devices determine the quality of the film.

In this article, we’ll take you on a tour of a thin-film production workshop and reveal the core equipment matrix—from raw materials to finished products. Let’s see how these “industrial powerhouses” transform ordinary plastic pellets into functional films tailored for various applications.

2025-11-28

The “Divine Easy-Tease Film” on milk tea cups: Simply peel it off—no sticking to your lips—and it’s packed with cutting-edge membrane technology.

This article dissects the “past and present” of bubble tea’s easy-peel film—from the frustrating issues with the old film to the cutting-edge technology behind the new one. What secrets does this film hold? And how should consumers and bubble tea shops make their choices?

2025-11-26

A Comprehensive Guide to Thin-Film Manufacturing: Unlocking the Performance Secrets of Membrane Materials—From Basic Formation to High-End Customization

Today, thin-film technology has entered a stage characterized by "material adaptation + process combination + performance customization." From shopping-bag films costing just a few cents to optical films priced at thousands of yuan, the manufacturing process directly determines the value. This article dissects mainstream processes, analyzes their advantages, application scenarios, and upgrade directions, providing practitioners with a framework for making informed choices.