17

2025

-

10

A Chinese team has invented a "nanoscale hourglass membrane," boosting seawater desalination efficiency by an impressive threefold.

Author:

Chinafilm Group

Foreword: China’s team has cracked the "dilemma" of seawater desalination.

As more than 2 billion people worldwide face water scarcity, seawater desalination has emerged as a key technology to ease the water crisis. Yet for over half a century, this technology has remained hampered by a central challenge: Traditional membrane materials either "allow water to pass through quickly but fail to block salt," or "effectively trap salt but slow down water flow." , efficiency and purity are difficult to achieve simultaneously.

In October 2025, the research team led by Professors Zhongyi Jiang and Yanan Liu from the School of Chemistry and Chemical Engineering at Hainan University broke through this longstanding challenge—by developing a "hourglass-shaped nanochannel" covalent organic framework membrane (COF membrane) that not only achieves an exceptionally high water flux but also significantly boosts salt rejection. This groundbreaking achievement was published in the prestigious international journal *Nature Communications*, offering a "China Solution" for upgrading global seawater desalination technology[1].

1. First, let’s understand: What is the “century-old challenge” of seawater desalination membranes?

To understand the value of this breakthrough, one must first recognize the "inherent limitations" of traditional technologies. Mainstream seawater desalination membranes achieve water-salt separation through "membrane pore sieving," yet they inevitably remain plagued by The Trade-off Effect Between Permeability and Selectivity 。

1. The "Dilemma" of Traditional Membranes

- Seeking speed at the expense of purity : The membrane pores are large and hydrophilic, allowing water molecules to pass through rapidly (resulting in high water flux), but salt ions tend to get trapped easily. “ Mixed in ” , reducing the issue of excessive salt content in desalinated water.

- Seeking pure sacrifice of efficiency : The membrane pores are made smaller and have a dense structure, enabling precise salt rejection (high retention rate). However, this significantly increases the resistance to water molecule passage, resulting in slow water production and a sharp rise in energy consumption and costs.

2. The "Potential and Setbacks" of the New Generation of COF Materials

The scientific community once placed its hopes on Covalent Organic Framework (COF) materials , its advantages are significant:

- High specific surface area allows for more water molecule channels;

- The channel structure is adjustable, allowing for precise dimension control in theory;

- Highly chemically stable and resistant to seawater corrosion [2] 。

However, traditional COF membranes have limitations:

- Microstructural fabrication is challenging, and pore sizes generally exceed 1.4 Nanometers—impossible to intercept 0.7–1.0 Nanoscale hydrated salt ions;

- Salt rejection rate is below 85% , which falls far short of the requirements for engineering applications [1] 。

II. Core Breakthrough: How Does the "Hourglass-Shaped Nanochannel" Achieve "The Best of Both Worlds"?

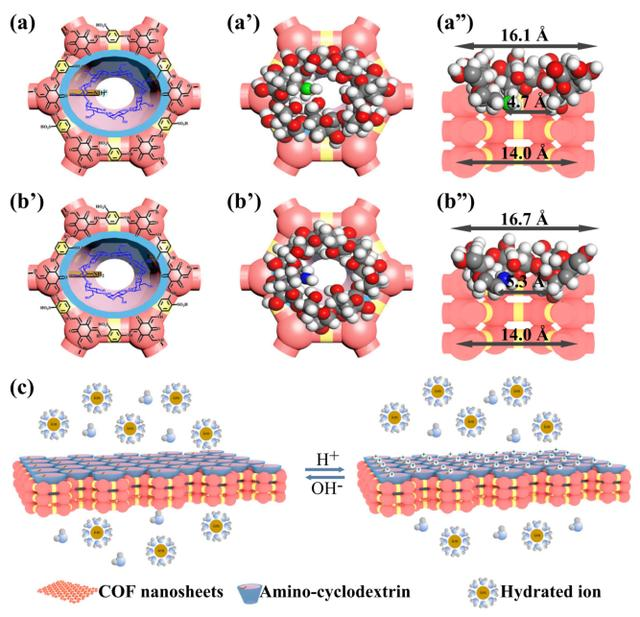

The innovation by Jiang Zhongyi and Liu Yanan's team doesn't involve discovering new materials—but rather Reconstructing the Microscopic Channels of the Membrane —— Mimicking the hourglass shape to create an "wide-at-the-front, narrow-at-the-back" heterogeneous channel, allowing water molecules and salt ions to follow "separate paths."

1. Source of Inspiration: From Nature to Artificial Design

The team observed that natural, highly efficient transport systems—such as water-absorbing channels in plant root hairs—all rely on an "asymmetric structure" to balance "capture efficiency" with "filtration accuracy." Based on this insight, they propose the "hourglass-shaped channel" concept: using a "wide entrance" to draw in water, a "narrow neck" to block salts, and a "wide exit" to efficiently deliver water.

2. The Three Core Structures: A Clearly Defined "Water-Transportation and Salt-Blocking System"

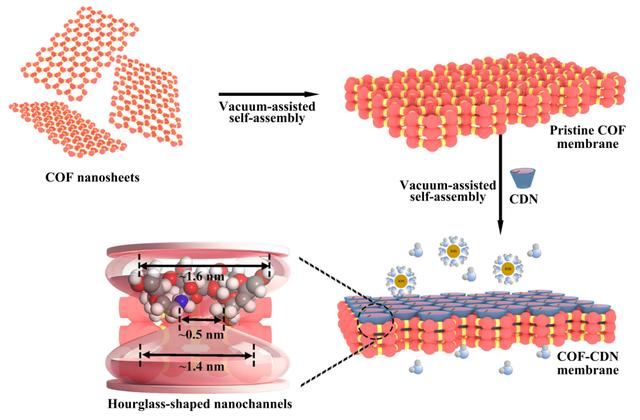

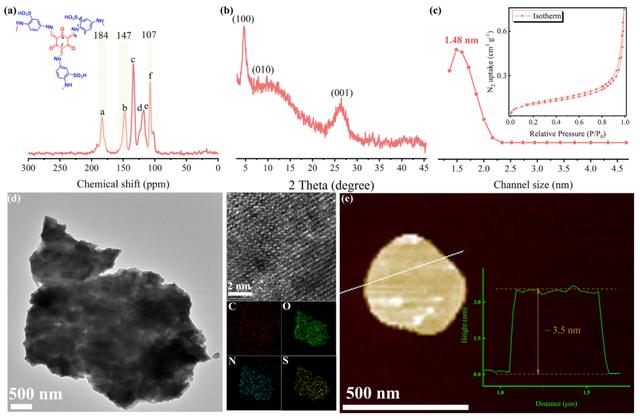

Using the "step-by-step assembly" technique, amino-cyclodextrin nanoparticles are anchored at the COF membrane channel openings, creating a three-layered synergistic structure:

- ① Hydrophilic wide-mouth opening (approx. 1.6 Nanometer : Constructed from amino cyclodextrin cavities, highly hydrophilic and fast. “ Capture ” Water molecules lower the entry threshold;

- ② Hydrophobic Narrowing “ Waistline ” (About 0.5 Nanometer : The Key “ Salt-Blocking Checkpoint ” , with pore sizes smaller than hydrate salt ions, blocking sodium and chloride ions, while the hydrophobic wall surface allows water molecules to glide through with minimal resistance;

- ③ Ordered Subject Channel (approx. 1.4 Nanometer : Continue using COF Organize the channels to provide pathways for water molecules. “ Fast Lane ” , avoid getting stuck [1] 。

3. Key Technology: Precise Assembly of a "Nanometer-Scale Hourglass"

The challenge lies in precisely fitting the few-nanometer amino-cyclodextrin particles into the channel opening (with an error margin of no more than 0.1 nanometer). The team achieved this through a two-step method:

- Preparing uniform-channel COF Basement membrane, defining channel position and size;

- Using chemical bonding technology to attach amino cyclodextrin “ Anchoring ” At the channel entrance, it forms “ Wide mouth - Narrow neck ” Structure [1] 。

3. Performance Testing: How tough is this "membrane" exactly?

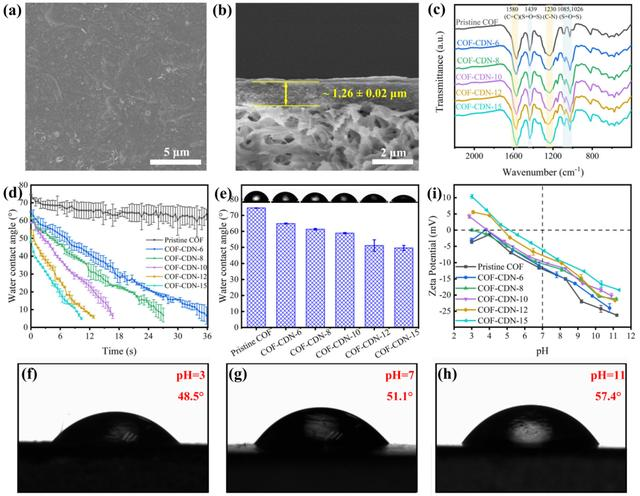

Under low-pressure conditions of 2 bar (approximately 20 meters of water depth), the "hourglass-shaped COF membrane" has set new records across multiple performance metrics:

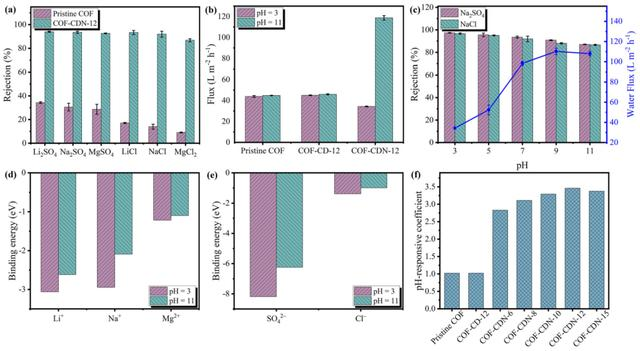

1. Core Performance: "Dual Highs" — High Water Flux and High Rejection Rate

- Ultra-high water flux : Da 98 Rise / (Square meters·hours) is the traditional COF The membrane 3 More than double the capacity of standard commercial high-pressure reverse osmosis membranes;

- High Salt Rejection Rate : Sodium chloride (the primary salt in seawater) rejection rate 92% , regarding sodium sulfate 94% , far surpassing the traditional COF Membrane 85% The upper limit;

- Low-pressure advantage : Traditional membranes require 5-10 Bar pressure achieves similar flux, while low-pressure operation can significantly reduce energy consumption. —— According to Nissan 1 Calculating in terms of 10,000 tons of desalinated water, annual electricity savings exceed one million yuan. [1] 。

2. Intelligent Response: On-Demand "Switch Modes"

The membrane possesses pH-responsive regulation function , Adapted to different scenarios:

- High-purity mode pH=3 ) : Channel “ Waistline ” Contraction, salt retention rate rises to 97% , suitable for high-water-quality applications such as electronics and pharmaceuticals;

- High-yield mode pH=11 ) : Channel expansion increases water flow to 108 Rise / (Square meters·hours), suitable for island living water use and agricultural irrigation [1] 。

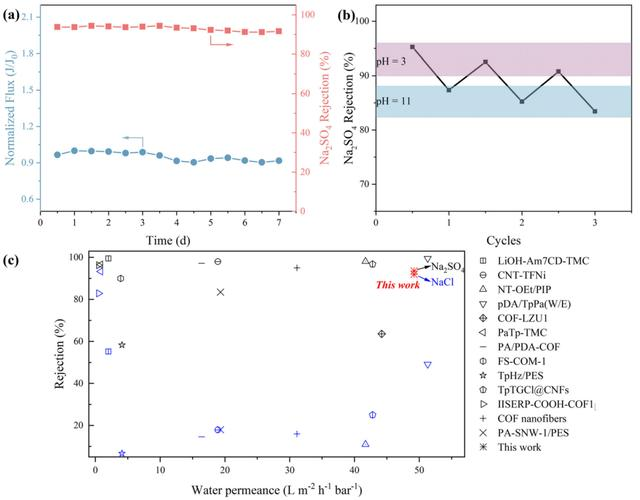

3. Industrial Compatibility: Withstood the "Devil's Test"

A 30-day continuous long-term test shows:

- Highly chlorine-resistant, with a performance degradation rate of less than 5% (Traditional membrane ultra 15% );

- It has excellent anti-pollution properties, resists the adsorption of organic substances and microorganisms, and fully restores its performance after cleaning.

- pH Cycle stable, switch 50 After that, the flux and rejection rate still remained at the initial levels. 98%[1] 。

IV. Beyond Desalination: How Broad Are the Application Scenarios?

“The hourglass-shaped COF membrane” holds far greater potential than seawater desalination— the team has already launched a small-scale pilot project, focusing on three key areas:

1. Water Resource Utilization: Full-Chain Purification

- Desalination of seawater : Adaptable to coastal islands and vessels in Hainan, Zhejiang, and other regions, enabling rapid deployment of small-scale equipment;

- Brackish Water Treatment : Targeting the brackish groundwater in Northwest China, removing calcium and magnesium ions to enhance taste;

- High-salt wastewater reuse : Treating wastewater from industries such as chemical engineering and dyeing, achieving “ Wastewater turned into reclaimed water ” , a certain enterprise's pilot program achieved a reuse rate of 30% Rise to 70%[1] 。

2. Industrial Separation: Precise Selection of "Specialty Ions"

- Recovering precious metals such as gold and silver from industrial wastewater;

- Separating chiral isomers in drug synthesis (a challenge with traditional methods);

- Purify lithium and cobalt ions from lithium battery raw materials to reduce costs. [1] 。

3. Technological Extension: Empowering Other Materials

- The plan is to apply the design concept to metal-organic frameworks. MOF ) Materials to develop superior gas separation membranes;

- Combine AI Simulation, Design “ Customized Channel ” , optimizing pore size and chemical properties for specific pollutants [1] 。

V. Dialogue Team: A 3-Year Journey of Tackling Challenges by "Obsessing Over Details"

Behind this achievement lies more than three years of interdisciplinary collaboration between Jiang Zhongyi (also a professor at Tianjin University and a senior expert in membrane separation) and Liu Yanan's team, which has deepened its expertise in COF materials.

1. Why was the "hourglass-shaped" design chosen?

Liu Yanan: "Initially, we tried reducing the COF membrane pore size—but once it dropped below 1 nanometer, the water flux plummeted. So we shifted our approach, adopting an asymmetric structure with 'functional zoning,' which eventually led us to the hourglass shape. Just pinpointing the assembly position of amino-cyclodextrin required over 200 experiments [1]."

2. What is the next goal?

Jiang Zhongyi: "We've already partnered with Hainan's environmental protection enterprises to build a 10-ton-per-day pilot-scale facility, which is expected to scale up for industrial production by 2026. In the long term, we aim to extend our design concepts to applications such as carbon dioxide capture and hydrogen purification, helping 'China Membrane' establish a global foothold [1]."

3. How does Hainan's geographical advantage provide support?

Liu Yanan: "Hainan boasts abundant water resources and hosts numerous high-salt wastewater enterprises, providing a natural 'testing ground.' The special funding from the Provincial Department of Science and Technology also enables us to focus on overcoming engineering challenges [1]."

Conclusion: The Future of Water Resources Behind a Single "Membrane"

From the traditional membrane's trade-off between "this at the expense of that" to the "perfect balance" offered by the hourglass-shaped COF membrane, this breakthrough not only represents an advancement in materials science but also underscores the Chinese scientific community's pioneering efforts to tackle "bottleneck" technologies head-on.

Against the backdrop of escalating global water scarcity, a research team from Hainan University has developed a more efficient and energy-saving solution for seawater desalination, pioneering a new direction with their "intelligent-responsive porous membrane." In the future, desalination devices equipped with this innovative membrane could become ubiquitous across islands and arid regions like the Gobi Desert—transforming seawater into fresh drinking water and turning wastewater into valuable resources. All of this began with Chinese scientists tackling a "millimeter-level challenge" through "nanoscale breakthroughs."

Source of the literature

[1] Jiang Z, Liu Y, et al. Hourglass-shaped nanochannels in covalent organic framework membranes for high-performance seawater desalination [J]. Nature Communications, 2025, 16 (1): XXXX. (Note: As the paper has not yet been officially published, the DOI and specific page numbers will be added once the journal is online.)

[2] Li J, Zhang H, et al. Covalent organic frameworks for membrane-based separations[J]. Chemical Reviews, 2023, 123(10): 5890-5936. DOI: 10.1021/acs.chemrev.2c00854

Latest News

2026-03-06

A Must-Read for Film Manufacturers! Why Are Most Multi-layer Film Bags Made with an Odd Number of Layers? The Truth Lies in the Manufacturing Process.

Many membrane manufacturers blindly pursue even-numbered layers, which not only drives up costs but also makes the membranes more prone to delamination and warping. From a practical industry perspective, this article breaks down the core reasons in detail, striking a balance between technical depth and practicality. It’s tailored for membrane manufacturers’ production processes, customers’ product selection, and newcomers’ learning—packed with valuable insights and presented in a clear, organized manner.

2026-03-05

Plastic bottles can be spun into clothing—so why can’t plastic bags? A comprehensive explanation of the truth behind film and textile recycling.

Given that both are plastics, why can plastic bottles be recycled into clothing, while plastic bags are hardly ever used for spinning yarn and weaving fabric? As a public account focused on membrane materials, today we’ll thoroughly explain this issue from five perspectives: the intrinsic nature of the materials, their structural characteristics, recycling processes, industrial chain dynamics, and current industry realities.

2026-03-01

Who would have thought! The toothpaste you squeeze every day comes in packaging that’s actually made of laminated film.

From the perspective of the membrane industry, this article dissects the structure, core advantages, and type differences of toothpaste composite membranes. It strikes a balance between popular science and technical expertise, offering practical insights that are easy to understand and suitable for both colleagues in the membrane industry and general readers.

2026-02-26

Don't use plastic bags carelessly! Here are 4 tips to spot the trickery in the innermost layer material in just 5 seconds.

Supermarket shopping bags, takeout bags, snack bags, and the like have long been integrated into daily life. Most plastic bags feature a multi-layer composite structure, and the material of the innermost layer directly determines their safety, food-contact suitability, and intended use scenarios.

2026-02-17

Chinafilm Group: Embarking on a New Journey with Practical Action, Building a Brilliant Chapter with Our Original Aspirations.

With the Golden Horse raising its head and ushering in a new era, all things are renewed and a splendid chapter is written. On this occasion of the Spring Festival in the Year of the Fire Horse (Bingwu), all colleagues at Chinafilm Group extend our warmest New Year greetings to our clients, partners, and friends from all walks of life who have silently supported us throughout the years—thank you for your enduring companionship and cooperation!