24

2025

-

07

Research and Application of a Novel Soft Pouch Film

Author:

Chinafilm Group

Introduction

In recent years, with the rapid development of the consumer goods industry and the increasing emphasis on green and environmental protection, flexible packaging, as a lightweight, efficient, and environmentally friendly packaging method, has been widely used in the food, pharmaceutical, daily chemical, and electronics industries. As one of the key basic materials for flexible packaging, flexible packaging films are also undergoing profound technological innovation.

Traditional flexible packaging films are mostly made of PE (polyethylene), PP (polypropylene), PET (polyester) and other base materials, processed through multiple processes such as co-extrusion, lamination, and aluminum plating. Although they have certain mechanical properties and barrier properties, they still have shortcomings in terms of puncture resistance, ductility, heat sealability, and environmental protection. With the breakthroughs in new technologies such as nanomaterials, functional coatings, and biodegradable materials, new flexible packaging films have emerged, becoming an important direction for technological upgrading in the packaging industry.

This article comprehensively analyzes this industry hotspot from multiple dimensions, including the definition, core technologies, performance advantages, practical applications, typical cases, and future trends of new flexible packaging films, providing a systematic cognitive framework and practical reference for material developers, packaging designers, brand owners, and end users.

I. Overview of New Flexible Packaging Films

1.1 Definition and Classification

New flexible packaging films generally refer to composite films or single-layer films developed based on traditional packaging films by introducing advanced material technologies, green and environmentally friendly concepts, and intelligent manufacturing methods, which have higher performance and stronger functionality. The main classifications are as follows:

- Functional flexible packaging films: such as high-barrier films, UV-resistant films, anti-fog films, antibacterial films, etc.;

- Nano-composite films: improving barrier properties and mechanical properties by introducing nanoparticles;

- Biodegradable films: using PLA 、 PBAT etc. as base materials, which are naturally degradable;

- High-strength heat-sealable films: structural films optimized for high-temperature heat-sealing equipment;

- Intelligent sensing films: which can achieve visible feedback such as temperature changes and light changes.

1.2 Main Performance Indicators

New flexible packaging films usually have significant improvements in the following key indicators:

- Barrier properties (such as oxygen transmission rate OTR , water vapor transmission rate WVTR );

- Mechanical properties (tensile strength, tear strength, puncture strength, etc.);

- Heat sealing properties (heat sealing starting temperature, heat sealing strength, heat sealing adaptability);

- Environmental protection performance (recyclability, degradability, carbon footprint, etc.);

- Surface properties (anti-fogging, hydrophilicity, printability, etc.);

- Additional functions (antibacterial, light-changing, flame-retardant, electromagnetic shielding, etc.).

II. Core Technological Breakthroughs

2.1 Nano-enhanced Technology

By introducing functional particles such as nano-montmorillonite, nano SiO ₂, and graphene, a maze-like structure can be formed in the polymer matrix, effectively blocking gas molecule channels, thereby significantly improving the gas and water vapor barrier properties of the material. Nano-montmorillonite enhanced PE film, OTR can be reduced to 1/10 of ordinary films; nano-silica coatings can give the film excellent anti-fogging and scratch resistance; graphene thin-layer composite films exhibit excellent thermal conductivity and antibacterial properties.

2.2 Multi-layer Co-extrusion Technology

Using five-layer, seven-layer, or even eleven-layer co-extrusion processes can achieve the division of labor and synergy of structural functions, such as:

- The inner layer has good heat sealability;

- The middle layer has strong barrier properties;

- The outer layer provides printability and mechanical strength.

Compared with traditional dry lamination, co-extrusion technology has more advantages such as integration, solvent-free, and energy saving and environmental protection.

2.3 Environmental Material Innovation

In order to meet the trend of sustainable development, many companies have invested in the research and development of biodegradable materials, such as:

- PLA+PBAT blend films, which combine mechanical properties and compostability;

- Bio-based PE/PP films, which have good compatibility with traditional products;

- Water-soluble films and water-based coating films are gradually being used in washable packaging and food portioning.

2.4 Surface Functional Modification

Using plasma treatment, electron beam treatment, water-based coatings, UV curing, etc., to improve the surface of the film:

- Coating adhesion;

- Ink absorption;

- Scratch resistance and anti-fingerprint ability;

- Anti-fogging, anti-static, and anti-sticking properties.

III. Application Fields of New Flexible Packaging Films

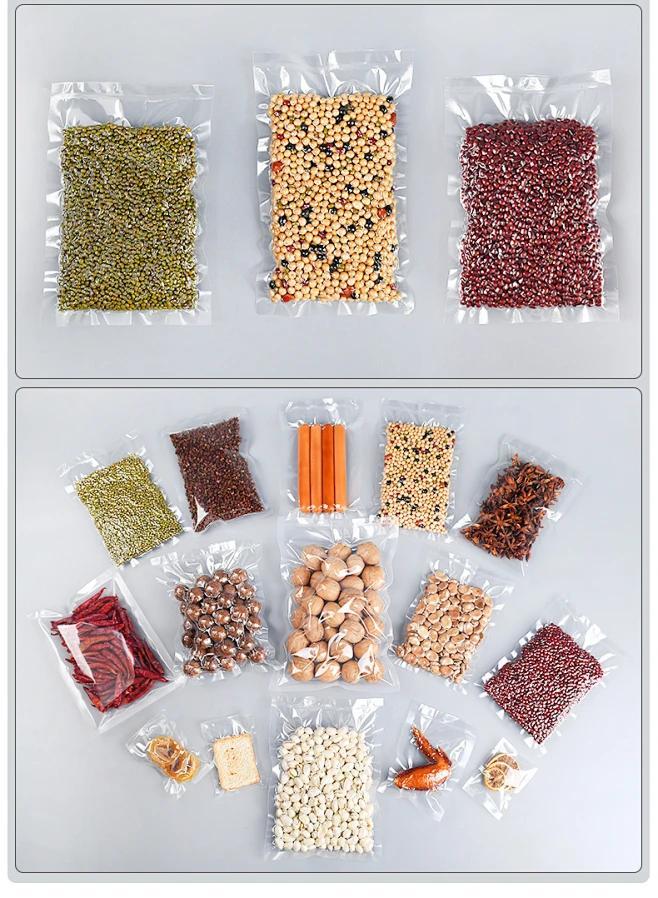

3.1 Food Packaging

This is the largest application market for flexible packaging films. New film materials are solving the following pain points:

- Barrier properties issues: using EVOH/SiO The composite structure prevents water vapor and oxygen penetration, extending shelf life;

- Heat sealing performance: Multilayer co-extruded films are highly adaptable to various temperatures and suitable for high-speed automatic packaging lines;

- Degradable requirements: PLA The base film is rapidly gaining popularity in disposable food packaging;

- Transparency requirements: Used for ready-to-eat fruits, vegetables, salad boxes, and other products with high display requirements.

3.2 Pharmaceutical and daily chemical packaging

More stringent requirements for film materials:

- High barrier + Non-migration: Prevents the volatilization or contamination of active ingredients;

- Easy-tear opening structure: Facilitates user access;

- Antibacterial surface layer: Improves the hygiene and safety of drug packaging;

- Hydrophilic coating + Printability: Suitable for cosmetic pouch products.

3.3 Industrial and electronic product packaging

Such as lithium battery soft packs, IC Anti-static bags for chips, etc. The main technical challenges are:

- Coexistence of corrosion resistance and high barrier properties;

- Excellent thermal stability and electrical insulation;

- Vacuum packaging or gas replacement function can be achieved;

- Anti-static, explosion-proof, and scratch-resistant treatment.

3.4 Fast-moving consumer goods and logistics packaging

In the increasingly developed e-commerce logistics scenario, new soft packaging films can be applied to:

- Stretch wrap film upgrade: Enhanced puncture resistance and resilience;

- Intelligent packaging: Built-in temperature change / Light change / Two-dimensional code modules for visual traceability;

- Personalized customized film materials: Low grammage, high-strength materials reduce usage and lower transportation costs.

IV. Typical Application Case Analysis

Case 1: A dairy company uses EVOH High barrier film

Goal: Extend the shelf life of cold chain yogurt products to 30 days or more

Solution: Using PET/EVOH/PE Seven-layer co-extruded film to replace the original dry composite film

Results:

- Oxygen permeability from 80 cc/m ²· day reduced to 3 cc/m ²· day ;

- Heat sealing strength improved 35% , reducing packaging damage;

- Customer return rate reduced 50% or more.

Case 2: PLA Promotion of degradable soft packaging film in the takeaway market

Customer: A leading takeaway platform

Demand: Promote "zero plastic meal packaging" and enhance the green image

Solution: Using PLA+PBAT Combination of blend film and water-based ink printing

Effect:

- Achieve fully compostable ( 60 days 90% or more degradation);

- Meets the commercial use requirements of heat sealing and printing;

- Obtained China's "Green Product Certification" and EU EN13432 certification.

Case 3: Domestic substitution project for aluminum-plastic film used in lithium batteries

Background: High domestic dependence on imported battery aluminum-plastic film, high cost

Challenges:

- Requires both high barrier properties and high ductility and puncture resistance

- Must meet stringent battery safety tests

Progress:

- A materials company uses " PP+PA+AL+PP " multilayer structure;

- Introducing nano-ceramic coating to improve pressure resistance and thermal stability;

- Cost reduction 20% , and mass delivery is achieved.

V. Challenges and Future Trends

5.1 Current challenges

- Environmental protection and performance are difficult to achieve simultaneously: Bio-based films still have problems such as weak heat sealing and high cost;

- Equipment compatibility issues: New film materials need to be compatible with various packaging equipment, and there are debugging difficulties;

- Lagging regulations and standards: Complex certification processes hinder market promotion;

- Insufficient industrial chain collaboration: Lack of cooperation mechanism from upstream resin manufacturers to downstream brand owners.

5.2 Future development trends

- Multifunctional integration: Such as barrier + Antibacterial + Heat sealing + Visualization + Degradable integrated composite structure;

- Green manufacturing: all-water process, solvent-free compounding, zero VOC emissions;

- Intelligent sensing film: thermosensitive / photosensitive / Electrochromic materials enable visualized packaging;

- High-end application expansion: such as flexible displays, medical drug delivery films, wearable packaging films, etc.;

- Localization and domestic substitution: Domestic flexible packaging film enterprises are accelerating the pace of import substitution and breaking through technological barriers.

Conclusion

The research and development of new flexible packaging films is not only an iterative upgrade of material technology, but also a key force in promoting the green, intelligent, and high-end transformation of the entire packaging industry. From breakthroughs in high-barrier performance to the introduction of intelligent sensing functions, from the widespread application of environmentally friendly degradable materials to the continuous innovation of new structural designs, new flexible packaging films are influencing our daily lives and industrial systems in an irreversible trend.

For enterprises, actively deploying the research and development and industrialization of new flexible packaging film materials can not only seize the high-end market but also help achieve the "dual carbon" strategy; for scientific research institutions, strengthening basic material research and cross-disciplinary integrated innovation will be an important path to opening up the future.

Driven by both technological evolution and market demand, the era of new flexible packaging films has arrived.

Soft bag film,Technological innovation

Previous

Previous

Latest News

2025-07-24

Research and Application of a Novel Soft Pouch Film

Chinafilm Group provides a comprehensive analysis of the new soft pouch film industry, covering its definition, core technologies, performance advantages, practical applications, typical cases, and future trends. This analysis offers a systematic cognitive framework and practical reference for material developers, packaging designers, brand owners, and end-users.

2025-07-23

Development and Prospect of Biodegradable Film Materials

Chinafilm Group will delve into the definition, types, R&D progress, application fields, and future development trends of biodegradable film materials, aiming to provide valuable reference for industry practitioners, researchers, and policymakers.

2025-07-18

Stretch film “not sticky enough” or “too sticky”? Understand the secret of stickiness in this article

Zhongmo Group comprehensively reveals the composition principle and common problems of cling film viscosity, and provides practical film selection suggestions and processing solutions to help you accurately select films, reduce losses, and improve efficiency.

2025-07-17

What should be paid attention to when using cling film packaging during the rainy season/high temperature weather?

As the last line of defense in packaging, the stability and weather resistance of stretch film directly affect the transportation safety and brand image of products. Therefore, rationally selecting stretch film with stronger weather resistance and taking corresponding measures in packaging and storage are key to improving packaging quality and reducing cargo damage rates.

2025-07-10

No more waste! 5 practical tips to save cling film usage

Saving cling film doesn't mean sacrificing safety; it means achieving true cost reduction and efficiency improvement through scientific methods and systematic optimization.