29

2025

-

08

Membrane Product Lifespan Comparison: Which Is More Cost-Effective for Long-Term Use?

Author:

Chinafilm Group

Preface

In modern life, film products are widely used in various fields, from the mobile phones and cars we use daily to architectural glass, all relying on different functional films. Due to differences in materials, processes, and usage environments, the service life of different film products varies greatly.

For consumers, understanding the service life of these film products not only helps us make wiser purchasing decisions but also enables effective cost control over long-term use. Today, Chinafilm Group will take you through an in-depth discussion on the service life of common film products and calculate which film is more cost-effective in the long run.

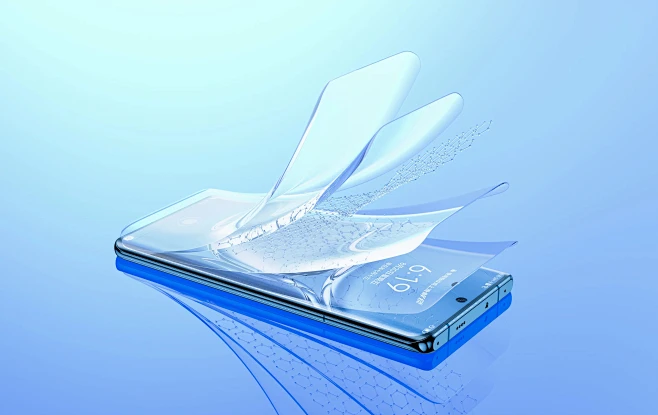

1. Mobile Phone Films: The Little Guardians Frequently Replaced

Mobile phones have become an indispensable part of our lives. To protect the phone screen, using a mobile phone film is almost standard. Common types of mobile phone films include plastic films, tempered glass films, and blue light blocking films.

(1) Plastic Film

Plastic films are relatively inexpensive but have weaker wear resistance and impact resistance. In daily use, scratches can easily appear if not careful, affecting screen clarity.

Generally, it is recommended to replace plastic films within 3 to 6 months. If your usage environment is harsh, such as frequently using your phone outdoors or on construction sites with more dust, the plastic film surface is more prone to accumulating dust and fine scratches, and its service life may be shorter, requiring replacement every 2 to 3 months.

(2) Tempered Glass Film

Tempered glass films are widely favored for their high hardness and good protective performance. Under normal use, tempered glass films can last about 6 months to 1 year. They effectively resist scratches from keys, coins, and other sharp objects, and can protect the screen from shattering to some extent if the phone is accidentally dropped.

However, if your phone frequently suffers heavy drops or often rubs against sharp objects during use, the tempered glass film may crack or scratch prematurely, requiring timely replacement to maintain screen protection.

(3) Blue Light Blocking Film

Blue light blocking films mainly address eye fatigue caused by prolonged phone use by filtering out some harmful blue light through special materials. Their service life is generally between 6 months and 1 year.

However, it should be noted that the blue light blocking effect may weaken over time. As usage time increases, the film surface may wear, affecting its blue light filtering ability. Moreover, if the blue light blocking film is of poor quality, it may yellow or have reduced light transmittance after some time, requiring timely replacement.

(4) Long-term Cost Analysis of Mobile Phone Films

Taking a plastic film priced at 20 yuan as an example, if replaced twice a year, the annual cost is 40 yuan. A tempered glass film priced at 50 yuan replaced once a year costs 50 yuan annually. Blue light blocking films are slightly more expensive; assuming one costs 80 yuan and is replaced once a year, the annual cost is 80 yuan.

In the long run, using plastic films results in a total cost of 40×5 = 200 yuan over 5 years; tempered glass films cost 50×5 = 250 yuan over 5 years; blue light blocking films cost 80×5 = 400 yuan over 5 years. Although plastic films have a low single purchase price, frequent replacements make the long-term cost not low. Tempered glass films balance protection performance and service life, with moderate overall cost. Blue light blocking films are more expensive, resulting in higher long-term costs, but for users with high eye protection needs, the health benefits may outweigh the cost difference.

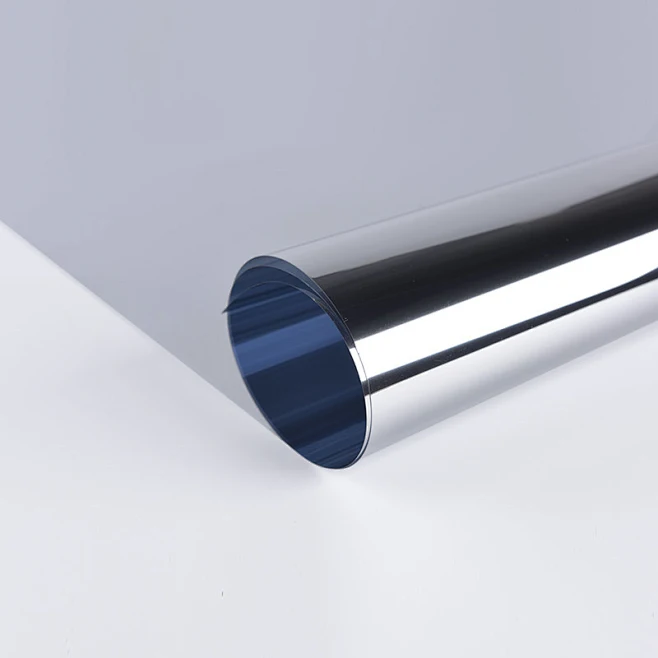

2. Car Films: The Barrier Protecting Your Beloved Car

Car films play a crucial role in the automotive field, providing heat insulation, sun protection, privacy protection, and paint protection. There are many types of car films, including solar films, invisible car paint protection films, and color change films, each with different service lives.

(1) Solar Films

- Tinted Film Tinted film is a relatively low-end type of solar film. It absorbs heat but does not insulate heat, with a short service life of about 1 year. This film is inexpensive, usually costing a few hundred yuan for a full car application. However, its quality is poor, prone to fading, and after some time, the color becomes uneven and blotchy, affecting appearance. Moreover, due to poor heat insulation, the car interior temperature remains high during summer, increasing air conditioning load and fuel consumption. Additionally, tinted films may emit odors harmful to occupants' health.

- Vacuum Heat Evaporation Film Vacuum heat evaporation films have poor clarity and severe reflection, with a service life of 2 to 3 years. This type of film achieves heat insulation and sunlight reflection by evaporating metal onto the film surface. Although heat insulation is average, over time, the film layer oxidizes, reducing heat insulation and clarity, affecting driving visibility. The price is generally around 1000 to 2000 yuan for a full car.

- Multi-layer Magnetron Sputtering Film Multi-layer magnetron sputtering films have high clarity and stable heat insulation, with a lifespan of over 5 years. They use advanced magnetron sputtering technology to evenly sputter various rare metals onto the film base, forming a multi-layer structure that effectively blocks ultraviolet and infrared rays, maintaining interior comfort. This film has good heat insulation, with total solar energy rejection rates around 50% to 70%. The price is relatively high, with full car film costs ranging from 3000 to 8000 yuan, but its stable performance and long-term use make the overall cost advantageous.

- 4S Shop Complimentary Films Some 4S shops offer free solar films when purchasing a car, but their service life is generally only 1 to 2 years. Although these films may seem fine initially, their quality varies. Over time, issues like fading, bubbling, and peeling may occur, affecting heat insulation and potentially causing driver fatigue. Some inferior films may emit toxic gases at high temperatures, endangering occupants' health.

(2) Invisible Car Paint Protection Film

- PVC Material Invisible Car Paint Protection Film PVC material invisible car paint protection film is relatively low in price, generally around 2000 - 5000 yuan. However, its service life is relatively short, about 1.5 years. PVC material is relatively hard and lacks flexibility; in daily use, slight impacts from stones or scratches from branches can cause film damage, failing to effectively protect the car paint. Moreover, PVC invisible car paint protection film has poor weather resistance, prone to fading and yellowing, and leaves adhesive residue when removed, damaging the original car paint.

- PU and TPH material invisible car paint protection films PU and TPH are upgraded materials from PVC, with improved durability after coating protection treatment. Under normal use, they generally last about 2.5 years, and with good maintenance, can reach 3.5 years. Their price usually ranges between 5000 - 8000 yuan. These two materials improve some of PVC's shortcomings, offering better flexibility and scratch resistance, but still have some gap compared to high-end materials.

- TPU material invisible car paint protection film TPU material invisible car paint protection film is currently the mainstream high-end product on the market. It features high tensile strength, high pull strength, and high toughness, effectively cushioning external impacts during daily driving to protect the car paint from damage. Some high-end TPU invisible car paint protection films also have self-healing functions; the elastic memory coating on the film surface can repair minor scratches at specific temperatures. Normally, TPU invisible car paint protection films have a service life of 5 years. With advanced coating technology protection and regular maintenance by the owner, some brand products can last 7 - 8 years. High-quality TPU material films, combined with careful owner care, can extend the service life to 10 years, which is not difficult. Of course, the price is relatively high, generally above 8000 yuan, with high-end products even exceeding 20000 yuan.

(3) Color Change Film

- PVC Color Change Film Traditional PVC color change films are relatively affordable; entry-level products from international brands cost about one-third of high-end invisible car paint protection films, with full car wrapping costs generally between 3000 - 6000 yuan. They meet owners' needs for personalized colors but have weak protective performance; slight scratches can cause damage and cannot protect the car paint. Moreover, PVC color change films have poor weather resistance, showing fading, yellowing, and edge lifting issues within 1 - 2 years. They leave adhesive residue or even damage the original car paint when removed, and the cost of later adhesive removal and paint repair often exceeds the cost of the film itself.

- TPU Color Change Film TPU color change films use TPU as the core base material, inheriting the protective qualities of invisible car paint protection films, while adding pigments to achieve color functionality. Their protective ability far exceeds that of PVC color change films and can effectively handle most daily damage scenarios. In terms of service life, TPU color change films typically last 3 - 5 years, significantly better than PVC color change films. Price-wise, a set of high-quality TPU color change films generally costs between 6000 - 12000 yuan. Although higher than PVC color change films, considering their protective performance and service life, the long-term cost is more advantageous.

(4) Long-term Cost Analysis of Car Films

Assuming a car is used for 10 years, let's compare the long-term costs of different car films.

- Sun Films :

- Tinted Film: replaced once a year, each time costing 800 yuan, total cost over 10 years is 800×10 = 8000 yuan.

- Vacuum Thermal Evaporation Film: replaced once every 2.5 years, each time costing 1500 yuan, replaced 4 times in 10 years, total cost 1500×4 = 6000 yuan.

- Multi-layer Magnetron Sputtering Film: replaced once every 6 years, each time costing 5000 yuan, replaced twice in 10 years (first replacement in year 6, second in year 10), total cost 5000×2 = 10000 yuan.

- 4S Shop Complimentary Film: assuming replacement once every 1.5 years (actual frequency may be higher), each replacement cost (including film removal, adhesive removal, and reapplication) is calculated at 1000 yuan, about 7 replacements in 10 years, total cost 1000×7 = 7000 yuan.

- Tinted Film: replaced once a year, each time costing 800 yuan, total cost over 10 years is 800×10 = 8000 yuan.

- Invisible Car Paint Protection Films :

- PVC Material: replaced once every 1.5 years, each time costing 3500 yuan, about 7 replacements in 10 years, total cost 3500×7 = 24500 yuan.

- PU and TPH Materials: replaced once every 3 years, each time costing 6500 yuan, replaced 3 times in 10 years (years 3, 6, and 9), total cost 6500×3 = 19500 yuan.

- TPU Material: replaced once every 7 years (assuming high-quality product and good maintenance), each time costing 15000 yuan, replaced twice in 10 years (years 7 and 10), total cost 15000×2 = 30000 yuan.

- PVC Material: replaced once every 1.5 years, each time costing 3500 yuan, about 7 replacements in 10 years, total cost 3500×7 = 24500 yuan.

- Color Change Films :

- PVC Color Change Film: replaced once every 1.5 years, each time costing 4500 yuan, about 7 replacements in 10 years, total cost 4500×7 = 31500 yuan.

- TPU Color Change Film: replaced once every 4 years, each time costing 9000 yuan, replaced 3 times in 10 years (years 4, 8, and 10), total cost 9000×3 = 27000 yuan.

- PVC Color Change Film: replaced once every 1.5 years, each time costing 4500 yuan, about 7 replacements in 10 years, total cost 4500×7 = 31500 yuan.

From the above data, it can be seen that among sun films, although multi-layer magnetron sputtering films have a high single purchase price, their long service life makes the long-term cost relatively reasonable; among invisible car paint protection films, TPU material, although expensive, offers comprehensive protective performance and service life, making the long-term cost reasonable and providing better protection for car paint; among color change films, TPU color change films have advantages over PVC color change films, with lower long-term costs and better protective performance.

3. Architectural Films: Guaranteeing Comfortable Spaces

In the architectural field, film products are also widely used, such as architectural glass films, which provide heat insulation, thermal retention, explosion resistance, and UV protection. Architectural films mainly have the following types and service life characteristics.

(1) Ordinary Heat Insulation Film

Ordinary heat insulation film uses relatively basic processes and materials, mainly achieving heat insulation by absorbing or reflecting heat. Its service life is generally around 3 to 5 years. During use, as time passes, the film's heat insulation performance gradually declines, and phenomena such as fading and bubbling may occur. The price ranges from 50 to 150 yuan per square meter.

(2) High-Performance Heat Insulation and Explosion-Proof Film

High-performance heat insulation and explosion-proof film has superior comprehensive performance, adopting a multi-layer composite structure and advanced heat insulation technology. It not only effectively insulates heat but also has good explosion-proof properties, preventing glass shards from splashing and injuring people when broken. Its service life usually reaches 5 to 10 years. This type of film is relatively expensive, costing about 150 to 300 yuan per square meter. Due to its long service life, it provides long-term stable heat insulation and safety protection for buildings, effectively reducing energy consumption and maintenance costs in the long run.

(3) Low-Emissivity (Low - E) Film

Low-emissivity film is a high-end architectural film that reduces the glass's emissivity by coating one or more layers of metal or metal oxide films on the surface, achieving excellent heat insulation and thermal retention performance. The service life of low-emissivity film can reach over 10 years, significantly improving building energy efficiency by reducing indoor heat loss in winter and outdoor heat gain in summer. Its price is relatively high, over 300 yuan per square meter, but for large buildings or high-end residences pursuing long-term energy savings and comfortable environments, the long-term cost advantage is significant.

(4) Long-Term Cost Analysis of Architectural Films

Taking a 100-square-meter building window as an example, assuming a usage period of 20 years.

- Ordinary Heat Insulation Film : Replaced once every 4 years, costing 100 yuan per square meter each time. Replaced 5 times in 20 years, with a total cost of 100×100×5 = 50,000 yuan.

- High-Performance Heat Insulation and Explosion-Proof Film : Replaced once every 7 years, costing 200 yuan per square meter each time. Replaced 3 times in 20 years (at years 7, 14, and 20), with a total cost of 200×100×3 = 60,000 yuan.

- Low-Emissivity (Low - E) Film : Replaced once every 12 years, costing 350 yuan per square meter each time. Replaced 2 times in 20 years (at years 12 and 20), with a total cost of 350×100×2 = 70,000 yuan.

Although the low-emissivity film has the highest single purchase price, due to its long service life and fewer replacements, the total cost over a 20-year usage period is not significantly disadvantageous compared to the other two films. Moreover, its energy-saving effect can save a large amount of energy costs in the long term, showing a significant overall cost advantage.

Conclusion

In summary, different types of films vary greatly in service life and long-term costs. When choosing film products, consumers should not only focus on the product price but also comprehensively consider its service life, performance, and their own usage needs and cycles. Only in this way can effective cost control be achieved in long-term use, obtaining the best user experience.Chinafilm Group, as a professional film product research and development and manufacturing enterprise, is always committed to providing customers with high-quality, long-life, and cost-effective film products to help everyone make wiser choices.

Latest News

2025-12-07

Today is Great Snow—The Middle Membrane is here with you, helping you ward off the chill of winter.

2025-12-05

The “Invisible Assistant” of 3D Printing: How Thin-Film Materials Are Rewriting the Rules of Printing?

This article unveils the “cross-border collaboration” between thin films and 3D printing: From platform protection to functional carriers—what secrets do thin films hold? And what technological breakthroughs will they drive?

2025-12-04

The “core equipment” for thin-film production: From particles to finished products, these devices determine the quality of the film.

In this article, we’ll take you on a tour of a thin-film production workshop and reveal the core equipment matrix—from raw materials to finished products. Let’s see how these “industrial powerhouses” transform ordinary plastic pellets into functional films tailored for various applications.

2025-11-28

The “Divine Easy-Tease Film” on milk tea cups: Simply peel it off—no sticking to your lips—and it’s packed with cutting-edge membrane technology.

This article dissects the “past and present” of bubble tea’s easy-peel film—from the frustrating issues with the old film to the cutting-edge technology behind the new one. What secrets does this film hold? And how should consumers and bubble tea shops make their choices?

2025-11-26

A Comprehensive Guide to Thin-Film Manufacturing: Unlocking the Performance Secrets of Membrane Materials—From Basic Formation to High-End Customization

Today, thin-film technology has entered a stage characterized by "material adaptation + process combination + performance customization." From shopping-bag films costing just a few cents to optical films priced at thousands of yuan, the manufacturing process directly determines the value. This article dissects mainstream processes, analyzes their advantages, application scenarios, and upgrade directions, providing practitioners with a framework for making informed choices.