24

2025

-

09

Under the wave of packaging automation, film products need to unlock these new features.

Author:

Chinafilm Group

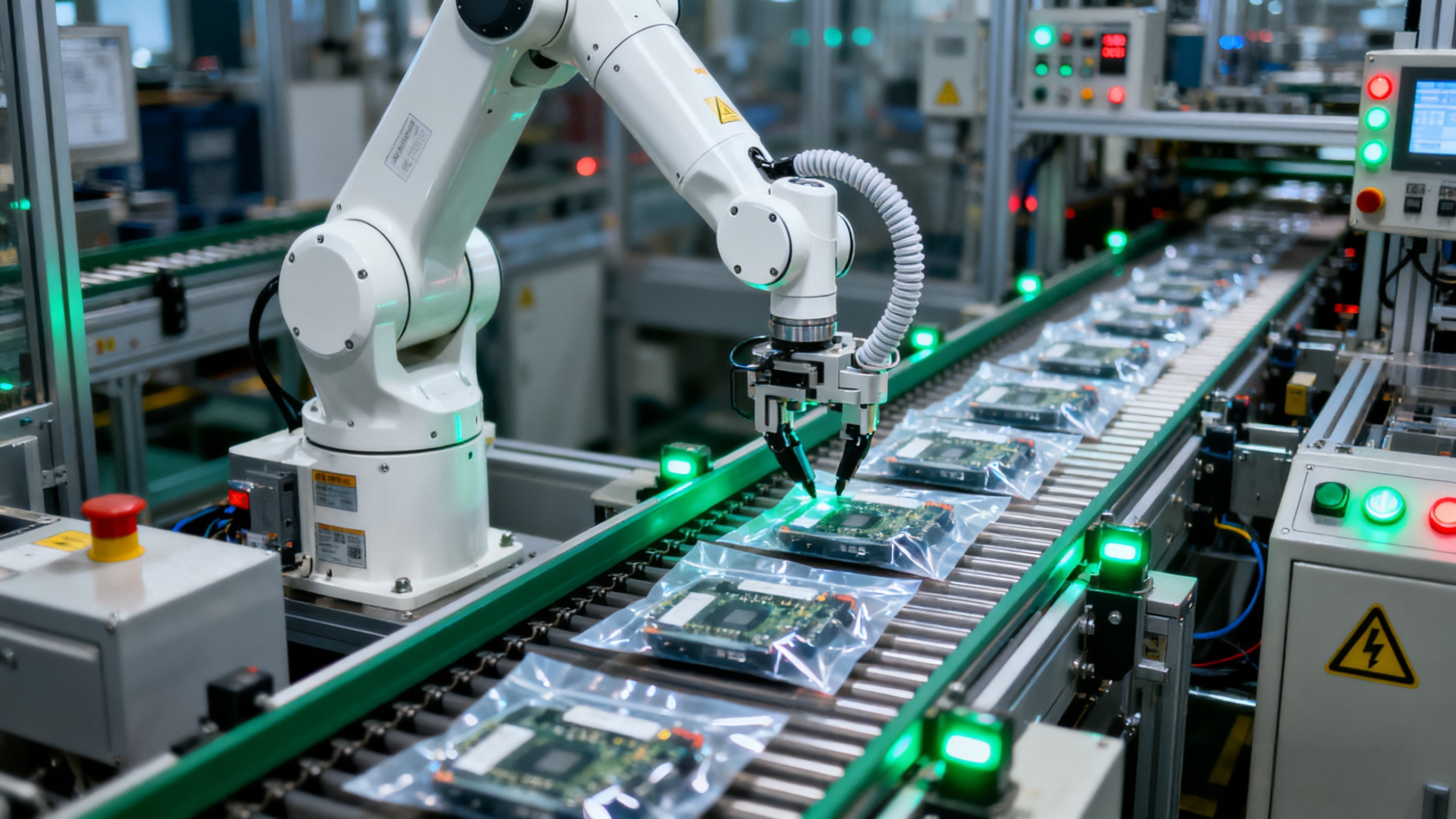

As the intelligent transformation of manufacturing accelerates, packaging automation has become a critical choice for companies seeking to reduce costs, boost efficiency, and enhance competitiveness. From automated wrapping on assembly lines to smart sorting and packaging in e-commerce warehouses, automation equipment is steadily replacing traditional manual operations.

As core materials in the packaging process, the performance of film products directly influences the efficiency, stability, and quality of automated packaging. Under this trend, film products must proactively adapt to the demands of automation equipment while unlocking even more innovative features.

I. Adapting to High-Speed Automation Equipment: The Core Requirement for Enhancing Packaging Efficiency

One of the core goals of packaging automation is "speeding up" (from a few pieces per minute by manual labor to dozens or even hundreds of pieces per minute with equipment). For film-based products, it’s essential to first ensure high-speed compatibility to prevent disruptions in the process or damage to the equipment.

1. Stable tensile performance to prevent high-speed breakage

- Problem scenario:

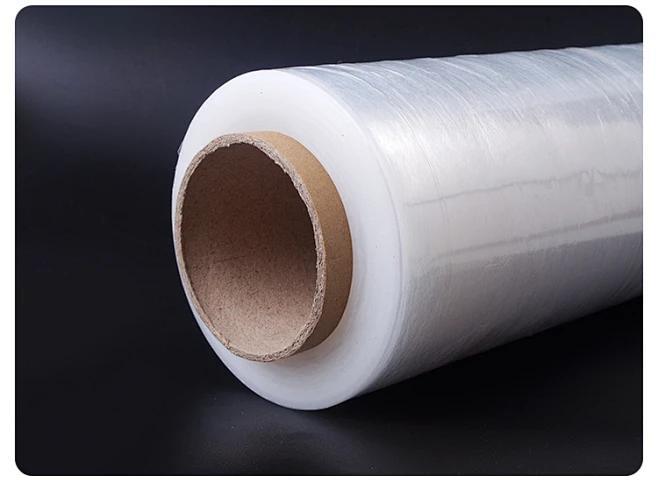

Automated equipment stretches film materials (such as stretch wrap) at a constant speed. However, if the tensile strength is uneven and tear resistance is poor, the film is prone to breaking at high speeds, leading to equipment downtime.

- Performance requirements:

- By using uniform raw material ratios and production processes, we ensure consistent longitudinal and transverse tensile strength.

- Under high-speed stretching (speed ≥ 30 meters/minute), the film must remain intact, without any cracks or tears.

- Real-life case:

When a logistics company used a high-speed stretch film packaging machine, the standard film resulted in an average of 5 to 8 downtime incidents per day. However, after switching to a specialized, high-tensile-strength film, downtime dropped to just 0 to 1 incident daily, boosting efficiency by 30%.

2. Precise dimension specifications reduce equipment debugging time

- Problem scenario:

Automated equipment has far stricter requirements for membrane width and thickness accuracy compared to manual processes. If deviations exceed ±2mm (in width) or if the thickness is uneven, it can easily lead to membrane misalignment and wrinkling, often requiring frequent manual adjustments.

- Performance requirements:

- Thickness Control: Real-time monitoring is conducted using a laser thickness gauge, ensuring that the thickness deviation for each roll of film is ≤0.005mm.

- Width Control: Processed using a high-precision slitting machine, with a deviation of ≤ ±1 mm.

- Core value: Reduce debugging frequency and ensure the seamless execution of automated processes.

3. Excellent unwinding smoothness, preventing film jams and delays.

- Problem scenario:

Automated equipment drives the film movement via a "rewinding mechanism." If the film roll has uneven tension—either loose or tight rolls—or if the edges are uneven, it can lead to film jams, delays, and disrupt the equipment's rhythm.

- Performance requirements:

- Winding Process: Ensure consistent tension throughout the film roll, with a diameter tolerance of ≤5mm and edges that are smooth and free of burrs.

- Core compatibility: The core of the film roll must match the dimensions of the equipment's unwind shaft (e.g., 3 inches, 6 inches), enabling "plug-and-play" functionality.

II. Compatibility with Multi-Scenario Packaging Needs: Breaking Through the Limitations of Single-Application Use

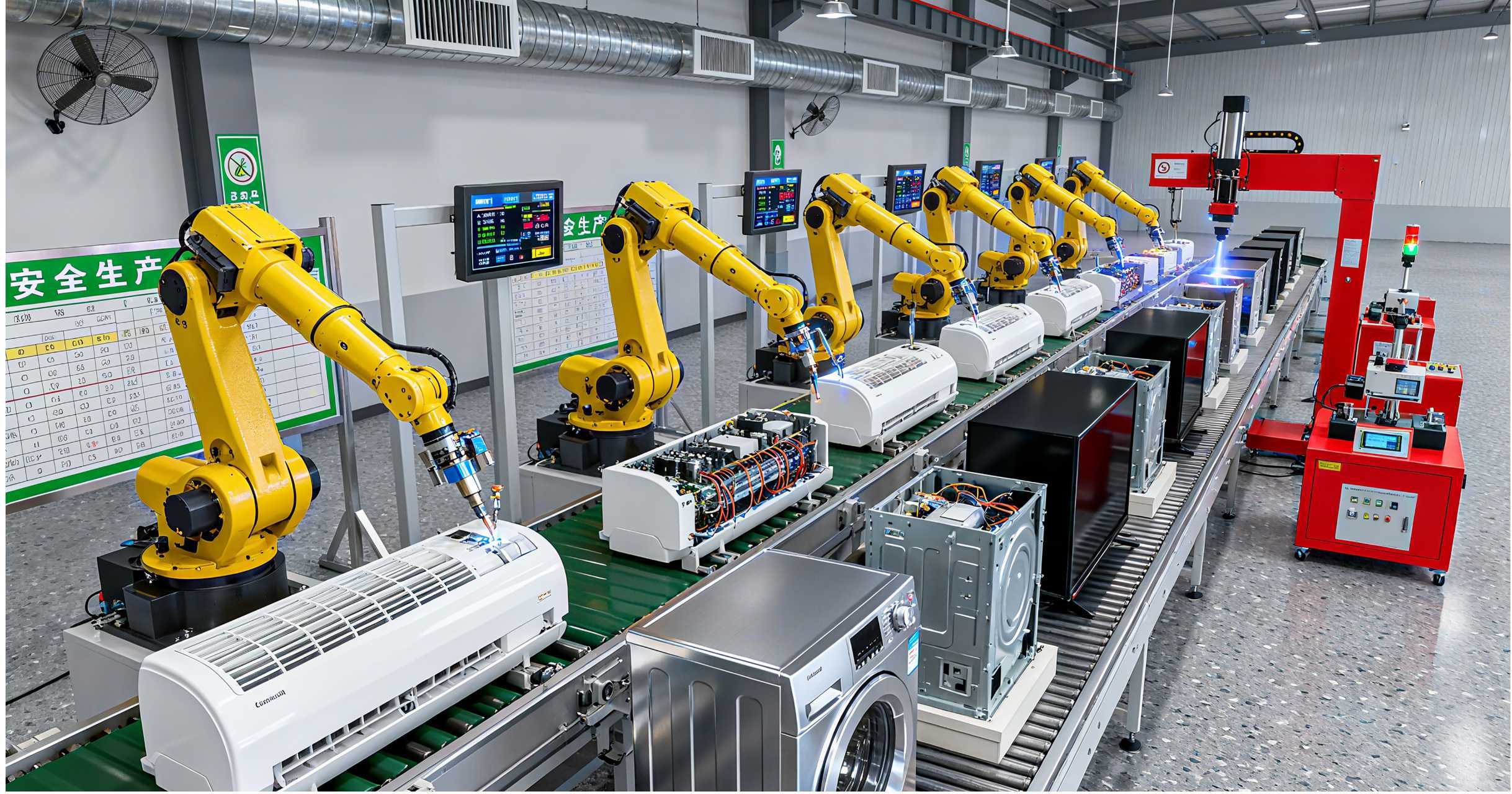

Automation packaging scenarios vary significantly across different industries—such as food, home appliances, and e-commerce—while film-based products need to move beyond single applications to meet diverse, evolving demands.

1. Temperature-resistant compatibility, designed to handle extreme packaging environments

- Scene 1: Automated Packaging for Food Cold Chain (Temperature –18℃ to 0℃)

- Question: Ordinary films are prone to becoming brittle and cracking.

- Solution: Develop a "low-temperature anti-cracking film" by adding cold-resistant additives, ensuring it retains flexibility even at -20°C.

- Scene 2: Electronic High-Temperature Sterilization Packaging (Temperature ≥80°C)

- Question: Ordinary films are prone to softening and deformation.

- Solution: Use a high-temperature-resistant substrate material (such as PET), which maintains structural stability below 100°C without melting.

2. Load-bearing and protection compatibility, meeting diverse product packaging needs

- Scene 1: Small, Lightweight Products (E-commerce items—just a few dozen grams)

- Requirements: Ensure package integrity, facilitate easy opening, and control costs.

- Feature: The film must be "lightweight, thin, and easy to tear," without increasing packaging costs.

- Scene 2: Heavy-duty equipment (machine tools, motors, several hundred kilograms)

- Requirement: Prevent displacement and damage during transportation, and provide protection against puncture by sharp objects.

- Feature: Utilizes a "high-strength heavy-duty film" with a longitudinal tensile strength of ≥20 MPa and excellent puncture resistance.

3. Compatible with special packaging formats, adapting to diverse device functionalities

Form 1: Shrink Packaging (Compatible with Shrink Wrapping Machines)

- Requirement: Rapid and uniform shrinkage after heating, with no wrinkles.

- Features:

- Shrinkage speed: After heating from 120°C to 180°C, shrinkage is completed within 10 seconds.

- Stable shrinkage rate: Longitudinal and transverse shrinkage rate deviations ≤3%.

Form 2: Vacuum Packaging (Compatible with Vacuum Packing Machines)

- Requirement: No air leakage after vacuuming, and resistance against puncture by sharp edges and corners.

- Feature: Equipped with "high-barrier properties + puncture resistance," ensuring stable vacuum conditions.

III. Balancing Environmental Protection and Costs: Aligning with Sustainable Development and Business Efficiency Needs

Environmental policies are becoming stricter, and automated packaging requires controlling long-term costs. Meanwhile, film products need to strike a balance between "green" initiatives and "cost-effectiveness."

1. Recyclable and biodegradable, reducing environmental impact

- Traditional issue: Conventional PE stretch film is single-use, difficult to degrade, and easily leads to "white pollution."

- Recycling direction:

- Develop single-material films (pure PE films, pure PET films) to avoid material mixing that leads to difficult recycling.

- The membrane surface is marked with recycling symbols for easy subsequent sorting and recycling.

- Biodegradable direction:

- Utilizing biodegradable materials (PBAT, PLA), these products fully degrade within 180 days in natural environments (soil / seawater).

- After degradation, no harmful substances remain, meeting environmental protection standards.

- Case: A certain e-commerce platform uses biodegradable courier packaging film, reducing plastic waste by over 500 tons annually.

2. High cost performance, helping to control long-term usage costs

- Cost challenge: Automated packaging film usage is 10%-15% higher than manual application, and if the unit price is high, the overall cost will increase.

- Cost Reduction Plan 1: Thin-Film Technology

- Premise: Ensure that tensile strength and puncture resistance remain unchanged.

- Instructions: Reduce the film thickness from 0.02 mm (traditional) to 0.015 mm, cutting down on material usage and lowering the unit price.

- Cost Reduction Plan 2: Enhance Usage Efficiency

- Method: Develop a "high-elongation film" with an elongation rate increased from 200% (traditional) to 300%. This allows the same length of film to wrap more products, reducing procurement volume.

3. Compatible with recycling automation, tailored for closed-loop packaging systems

- Future Trend: Packaging automation is evolving toward a "closed-loop system" (use → automated recycling → reprocessing → reuse).

- Adaptation Requirement 1: Easy to Sort

- Instructions: Add a fluorescent identifier to make it easier for automated optical sorting equipment to recognize the film's material/type.

- Adaptation Requirement 2: Recyclability-Resistant Processing

- Instructions: Ensure the film meets thermal stability standards to prevent uneven melting during automated pelletizing equipment operation, which could compromise the quality of recycled materials.

IV. Intelligent Empowerment: Achieving Full-Process Traceability in Packaging

Automation in packaging is evolving from simply "speeding up" to "intelligent control," and film-based products must become a "data link," enabling full-process traceability.

1. Integrate identifiable identifiers to seamlessly connect data pathways

- Core requirement: Enterprises need to monitor the usage of membranes, packaging product information, and batch details in real time.

- 方案 1: Surface-printed QR Code / Barcode

- Operation: The automated packaging equipment reads the film’s batch, specifications, and manufacturer information using a barcode scanner.

- Integration: Link the order numbers and quantities of packaged products, then upload them to the company's ERP system.

- 方案 2: Built-in RFID Chip (High-End Applications)

- Chip requirement: Ultra-high-frequency chip, with dimensions ≤5mm.

- Function: The automated equipment uses an RFID reader to instantly track the film usage progress and packaging location, enabling seamless data exchange among "film - product - equipment."

- Case: A certain automotive parts company implemented RFID-wrapped film, boosting the efficiency of tracing problematic films by 80%.

2. Equipped with quality alert functionality to reduce the rate of defective products.

- Pain point: In automated processes, membrane quality issues—such as thickness variations and insufficient tensile strength—easily lead to batch defects, and manual inspection struggles to detect these problems in real time.

- 方案 1: Embed Stress-Inducing Points

- Trigger condition: When the automated equipment stretches the stretch film, stress exceeds the preset value (posing a risk of breakage).

- Warning action: The sensing point sends an optical signal back to the device sensor, causing the equipment to slow down/shut down and trigger an alarm.

- 方案 2: Add a Temperature and Humidity-Sensing Coating (Cold Chain Applications)

- Trigger condition: Environmental temperature and humidity exceed the normal range.

- Warning action: Coating color changes; automated visual inspection equipment identifies and marks abnormal packaging to prevent product damage.

Conclusion: Membrane products must embrace the automated future with "adaptability."

Packaging automation involves the restructuring of the entire packaging system, and upgrading the characteristics of film-based products is key.

- From "passive adaptation" to "proactive upgrading," centered on automation needs while balancing efficiency, versatility, environmental sustainability, and intelligence.

- Future Challenges: We must address the trends of "unmanned operations" and "flexibility" (such as intelligent packaging robots for adaptive products), requiring dynamic shape adaptation and seamless integration with AI-powered vision systems.

- Key recommendation: Film companies need to collaborate with equipment manufacturers and end-user enterprises, leveraging material innovation and process optimization to become a "booster" for packaging automation—rather than a "roadblock."

Latest News

2025-09-26

Wrap Film vs. Protective Film: Stop the Confusion—One Article Clearly Explains the Key Differences

In the fields of packaging, transportation, and product protection, "stretch film" and "protective film" are often confused—and even casually interchanged during use—leading to issues such as goods scattering or products getting scratched. In fact, these two types have vastly different design intentions, functional characteristics, and application scenarios. This article will break down their distinctions across 8 key dimensions, helping you quickly identify the differences and make the right selection every time.

2025-09-24

Under the wave of packaging automation, film products need to unlock these new features.

As core materials in the packaging process, the performance of film products directly influences the efficiency, stability, and quality of automated packaging. Under this trend, film products must proactively adapt to the demands of automation equipment while unlocking even more innovative features.

2025-09-20

What are the storage conditions for different membrane products? How do temperature and humidity affect their shelf life?

Different types of films have vastly varying storage requirements for temperature and humidity due to differences in materials and manufacturing processes. This article will break down the specific storage conditions for common film types, as well as explain the precise impact of temperature and humidity deviations on shelf life.

2025-09-19

Chinafilm Group Shines at the 2025 Chongqing Top 100 Private Enterprises Press Conference

2025-09-18

Remember history, let us strengthen ourselves.

Commemorating the 94th Anniversary of the "September 18" Incident