26

2025

-

09

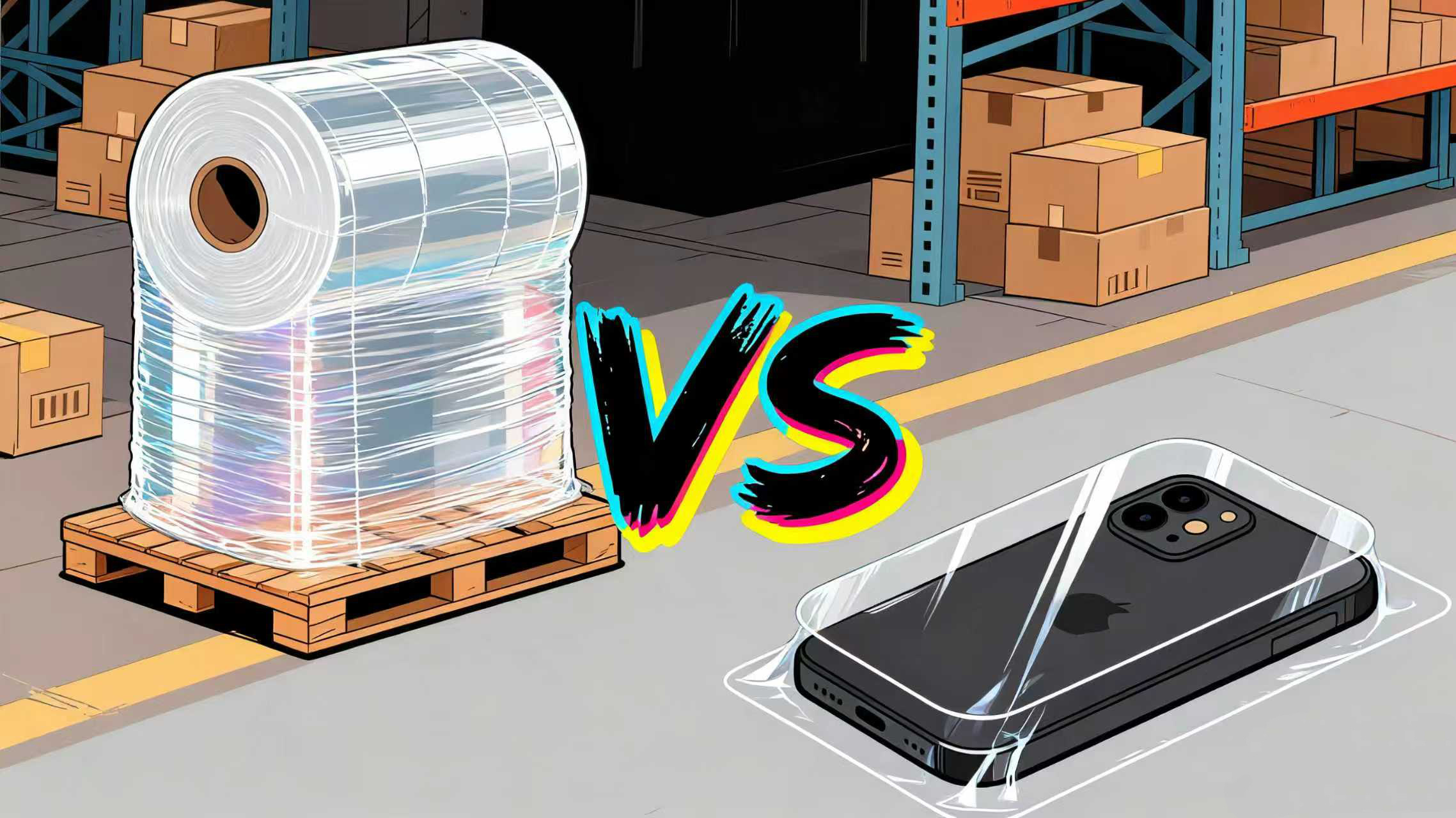

Wrap Film vs. Protective Film: Stop the Confusion—One Article Clearly Explains the Key Differences

Author:

Zhongmo Group

Preface

In the fields of packaging, transportation, and product protection, "stretch film" and "protective film" are often confused—and even casually interchanged during use—leading to issues such as goods scattering or products getting scratched. In fact, the two films differ significantly in their original design intentions, functional characteristics, and application scenarios. This article will break down these distinctions across 8 key dimensions, helping you quickly identify the differences and make the right selection every time.

I. Basic Definition: Understanding the Essential Differences Through "Design Purpose"

1. Stretch Film: The "Securing Guardian" of the Transportation Process

- Also known as "stretch film," its core attribute is Transportation Packaging Materials ;

- Design purpose: To bundle boxed or stacked goods into a unified unit, preventing them from scattering or shifting during transportation while also shielding them from dust.

- Core logic: Use "tensile force" to securely hold the cargo in place, emphasizing "collective stabilization" rather than striving for meticulous protection of individual items.

2. Protective Film: The "Surface Shield" for Your Entire Lifecycle

- Also known as "pre-applied film," its core attribute is Product Surface Protection Material ;

- Design purpose: To protect the surfaces of semi-finished and finished products, preventing scratches and stains during production, warehousing, transportation, and installation.

- Core logic: Attach to the product surface to form a "temporary protective layer," which is removed before use, ensuring the product "arrives brand-new straight from the factory."

II. Appearance and Material: Quickly Distinguish Using "Hand Feel + Form"

1. Appearance and Material Characteristics of Stretch Film

- Color: Based on Transparent Primarily, a few scenes use black (for shading) and blue (in batches);

- Thickness: 50–120 microns (μm); the thinner it is, the higher the elongation rate, making it ideal for lightweight goods.

- Feel: The surface is smooth with slight stickiness (adhesive/cohesive type), easily stretches when pulled, but doesn’t snap back when released.

- Shape: Roll-shaped, typically 50–60 cm wide and ranging from several hundred meters to over a kilometer in length, suitable for manual or machine winding.

2. Appearance and Material Characteristics of the Protective Film

- Colors: In addition to transparent, we offer functional options such as milky white (UV protection), blue (easy removal), and black.

- Thickness: 20–200 micrometers (μm); for heavy-duty products, the specialized film can exceed 300 μm.

- Feel: Consists of a "base material layer" and a "adhesive layer," where the adhesive's tackiness is adjustable (from low to high). When stretched, it exhibits low elongation and maintains crispness, making it resistant to deformation.

- Form: Primarily roll-shaped, with width customized as needed (from a few centimeters to several meters); special products can also be made in "sheet-like" forms.

III. Core Performance: From "Tensile Strength" to "Viscosity"—the Difference Is Clear at a Glance

1. The core performance of stretch film: focusing on "tensile strength" and "wrapping force."

- Elongation rate: A key metric—standard models range from 150% to 300%, while high-stretch models reach up to 500%, ensuring a snug wrap around your cargo.

- Puncture resistance: Withstands punctures at the edges and corners of goods, preventing tears during wrapping (e.g., higher requirements for items like parts or computer cases).

- Self-adhesive: Single-sided / double-sided adhesion, with low tackiness (only 1/5 to 1/10 of that of a protective film)—intended solely for laminating films together, not for adhering to surfaces or objects.

- Temperature resistance: -10°C to 60°C, suitable only for transportation at room temperature.

2. Core performance of the protective film: focusing on "protection" and "compatibility."

- Adhesion: Precisely controllable (low adhesion: 5–10 g/25 mm, medium adhesion: 20–50 g/25 mm, high adhesion: 80–150 g/25 mm), requiring compatibility with product materials to prevent damage.

- Peel strength: Removes cleanly without leaving residue and without damaging the product surface (such as paint or coatings); the peel strength exhibits minimal variation over time.

- Wear Resistance: Resists minor friction (such as handling and collisions), preventing membrane damage that could expose the product.

- Weather Resistance: The outdoor version withstands temperatures from -40°C to 120°C and offers protection against UV rays and rain (e.g., used as protective films for architectural panels, doors, and windows).

4. Application Scenarios: See "Where It's Used"—Quickly Tell the Difference

1. Typical Application Scenarios of Stretch Film

- Logistics Transportation: Palletized goods wrapped (in cardboard boxes, plastic crates, or drummed items), securing multi-layered cargo to prevent collapse;

- Warehouse Stacking: Arrange parcels in outer layers to prevent dust and keep them from loosening;

- Temporary Covering: Construction Site / Warehouse—Temporary tools and materials for covering (not suitable for long-term use);

- Specialized industries: Food-grade packages for fresh produce and bread (meeting food-contact standards), and sterile packages for medical devices.

2. Typical Application Scenarios for Protective Films

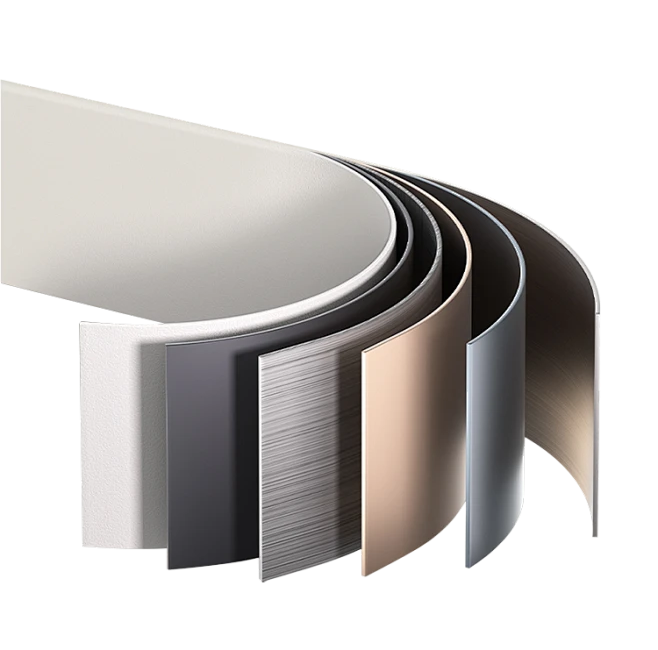

- Building materials industry: Tiles, stones, aluminum profiles, and door & window surfaces—protect against scratches during processing/transportation; remove after installation.

- Electronics industry: Mobile phone screens, computer casings, and appliance panels—protected against scratches during the sales process before leaving the factory;

- Automotive industry: New car paint finishes (temporary films), as well as components like bumpers and doors—protecting them from damage during production and assembly;

- Metal Industry: Stainless steel plates, aluminum plates, and galvanized sheets—cutting, handling, and storage designed to prevent oxidation and scratches.

V. Usage: "Wrapping" and "Pasting"—the operations are entirely different

1. How to Use Stretch Film

- Artificial Wrapping (Small Batch / Irregular Goods):

- The roll is secured to the hand or a holder, with one end pressed against the bottom of the cargo.

- Rotate around the goods, gently pull the film (stretch ratio of 100%-200%) to ensure a snug fit;

- Wrap upward, overlapping each coil by 1/2 to 1/3, then trim, press, and secure in place.

- The roll is secured to the hand or a holder, with one end pressed against the bottom of the cargo.

- Machine wrapping (large-scale / palletized goods):

- Place the goods onto the wrapping machine turntable, then set the number of layers, stretch rate, and rotation speed.

- The machine automatically stretches, wraps, and cuts the film, achieving an efficiency 5 to 10 times greater than manual labor.

- Place the goods onto the wrapping machine turntable, then set the number of layers, stretch rate, and rotation speed.

2. How to Use the Protective Film

- Hand-applied adhesive (small size / custom-shaped products):

- Clean the product surface (remove dust and oil stains, prevent bubbles);

- Peel-and-stick paper (directly applied without release liner); align the adhesive layer with the surface.

- Paste from one end to the other, press down to remove air bubbles, and trim off any excess.

- Clean the product surface (remove dust and oil stains, prevent bubbles);

- Automated Pasting (for Mass/Standardized Products):

- Labeling machine / Laminating machine automatically completes "cleaning - film removal - application - pressing";

- The electronics industry (such as mobile phone screens) uses fully automatic laminating machines with an accuracy of ±0.1mm, ensuring bubbles are prevented from shifting during the process.

- Labeling machine / Laminating machine automatically completes "cleaning - film removal - application - pressing";

6. Key Purchasing Points: Avoid the trap of "choosing the wrong film"—focus on these 3 critical factors.

1. Stretch film selection: Consider "cargo weight + transportation environment"

- Cargo weight:

- Lightweight (≤50kg): Choose the 50-80μm thin type with high elongation (200%-300%);

- Medium weight (50–200 kg): Choose the 80–100 μm medium-thickness, high-puncture-strength model;

- Weight (≥200kg): Choose the 100–120μm thick model, or opt for double-layer wrapping.

- Lightweight (≤50kg): Choose the 50-80μm thin type with high elongation (200%-300%);

- Transportation Environment:

- Room Temperature: Standard PE Wrap Film;

- Low Temperature (Cold Chain): Low-Temperature Resistant Model (-20°C);

- Light-shielding requirement: Black wrapping film.

- Room Temperature: Standard PE Wrap Film;

2. Protecting film selection: Consider "product material + usage duration"

- Product material:

- Smooth surfaces (glass, metal panels): Low-to-medium tack film, leaving no adhesive residue;

- Rough surfaces (frosted plastic, stone): High-adhesion film ensures a secure fit;

- Easily damaged surfaces (paint, acrylic): Low-tack + low-peel adhesive film to prevent surface damage.

- Smooth surfaces (glass, metal panels): Low-to-medium tack film, leaving no adhesive residue;

- Usage cycle:

- Short-term (1–3 months, logistics): Standard film;

- Mid-term (3–12 months, warehousing): Slightly more weather-resistant model;

- Long-term (≥12 months, building exterior walls): UV-resistant + anti-aging specialized film.

- Short-term (1–3 months, logistics): Standard film;

VII. Common Misconceptions: Stop Making These "Assumptions" Any Longer

Misconception 1: Using stretch film instead of protective film to cover product surfaces

- Consequences: Low adhesion leads to easy detachment and inability to provide scratch resistance; stretching or shrinking may cause product deformation (e.g., panels, screens).

- Correct: Select the corresponding protective film based on the product material.

Misconception 2: Wrapping palletized goods with protective film

- Consequences: Low stretchability leads to poor wrapping tightness, making goods prone to scattering; the protective film incurs high costs, resulting in waste.

- Correct: Palletized goods are secured with stretch film, prioritizing "stability" over "meticulous protection."

Misconception 3: Believing that "the thicker the film, the better."

- Truth: Excessively thick stretch film reduces the stretching rate, actually making it harder to wrap tightly; overly thick protective film increases costs and makes removal more difficult.

- Correct: Select the appropriate thickness based on the weight of the goods and the material of the product.

Misconception 4: Overlooking the "residual adhesive" issue

- Consequences: Choosing the wrong adhesive (e.g., high-tack for painted surfaces) can leave residual glue behind, making removal difficult and cleanup a hassle.

- Correct: Test the product with a small sample before purchasing to ensure there’s no adhesive residue, then proceed with bulk use.

Conclusion

Stretch film is the "transportation and securing expert," while protective film serves as the "surface safeguard." Though both belong to the "film family," their core functions and application scenarios don’t overlap at all. We hope this article helps you clearly distinguish between the two, so you can avoid common pitfalls when purchasing and using them. If you have specific questions—like "Which type of film should I choose for a particular product?"—feel free to leave a comment in the discussion section! And don’t forget to like, save, and share this post with friends who might find it helpful!

Previous

Previous

Latest News

2025-09-26

Wrap Film vs. Protective Film: Stop the Confusion—One Article Clearly Explains the Key Differences

In the fields of packaging, transportation, and product protection, "stretch film" and "protective film" are often confused—and even casually interchanged during use—leading to issues such as goods scattering or products getting scratched. In fact, these two types have vastly different design intentions, functional characteristics, and application scenarios. This article will break down their distinctions across 8 key dimensions, helping you quickly identify the differences and make the right selection every time.

2025-09-24

Under the wave of packaging automation, film products need to unlock these new features.

As core materials in the packaging process, the performance of film products directly influences the efficiency, stability, and quality of automated packaging. Under this trend, film products must proactively adapt to the demands of automation equipment while unlocking even more innovative features.

2025-09-20

What are the storage conditions for different membrane products? How do temperature and humidity affect their shelf life?

Different types of films have vastly varying storage requirements for temperature and humidity due to differences in materials and manufacturing processes. This article will break down the specific storage conditions for common film types, as well as explain the precise impact of temperature and humidity deviations on shelf life.

2025-09-19

Chinafilm Group Shines at the 2025 Chongqing Top 100 Private Enterprises Press Conference

2025-09-18

Remember history, let us strengthen ourselves.

Commemorating the 94th Anniversary of the "September 18" Incident