30

2025

-

07

Nano-wrapped film: The engine of a new era of high-performance packaging

Author:

Chinafilm Group

I. Introduction: Upgrading from Traditional Stretch Film to Nano Stretch Film

Stretch film, also known as stretch wrap ( Stretch Film ), is a flexible packaging material widely used in logistics, warehousing, food, medicine, electronics, and other fields. It is mainly used for palletized packaging of goods, using its self-adhesive and high elasticity to achieve dustproof, moisture-proof, anti-loosening, and anti-theft protection of goods. Traditional stretch film is mainly made of linear low-density polyethylene ( LLDPE ), and performs well in ensuring basic packaging functions. However, with the market's increasing demands for transportation safety, material saving and environmental protection, functionality, and intelligence, its performance bottlenecks are becoming increasingly apparent.

To break through these bottlenecks, nanotechnology has emerged and rapidly penetrated the stretch film material system, giving rise to a new generation of high-performance "nano stretch film". By introducing nanometer particles, nano-layered materials, nanofibers, nanocapsules, and other structural units into the polymer matrix, nano stretch film has achieved a leapfrog improvement in mechanical properties, barrier properties, puncture resistance, self-adhesiveness, thermal stability, and even intelligent responsiveness.

This article will comprehensively and systematically introduce the basic theory, key properties, material composition, preparation process, typical applications, current challenges, and future development directions of nano stretch film, helping readers to fully understand the technical core and market potential of this disruptive material system.

II. Basic Definition and Material Structure of Nano Stretch Film

2.1 Definition and Classification

Nano stretch film refers to a new type of stretch packaging material that is made by adding nanometer-scale functional fillers or constructing nanostructures ( 1~100nm 、 scale) into traditional stretch film material systems (such as PE PLA etc.) to enhance the performance and expand the functions of the film.

According to the different nanostructures, it can be mainly divided into:

- Nanoparticle-enhanced stretch film: adding nano SiO ₂, TiO ₂, ZnO etc.;

- Layered nanosheet-filled stretch film: such as montmorillonite ( MMT ), graphene;

- Nanofiber composite stretch film: such as nanocellulose ( CNF );

- Multifunctional nanocomposite stretch film: with antibacterial, flame-retardant, conductive, and other properties.

2.2 Typical Structural Diagram

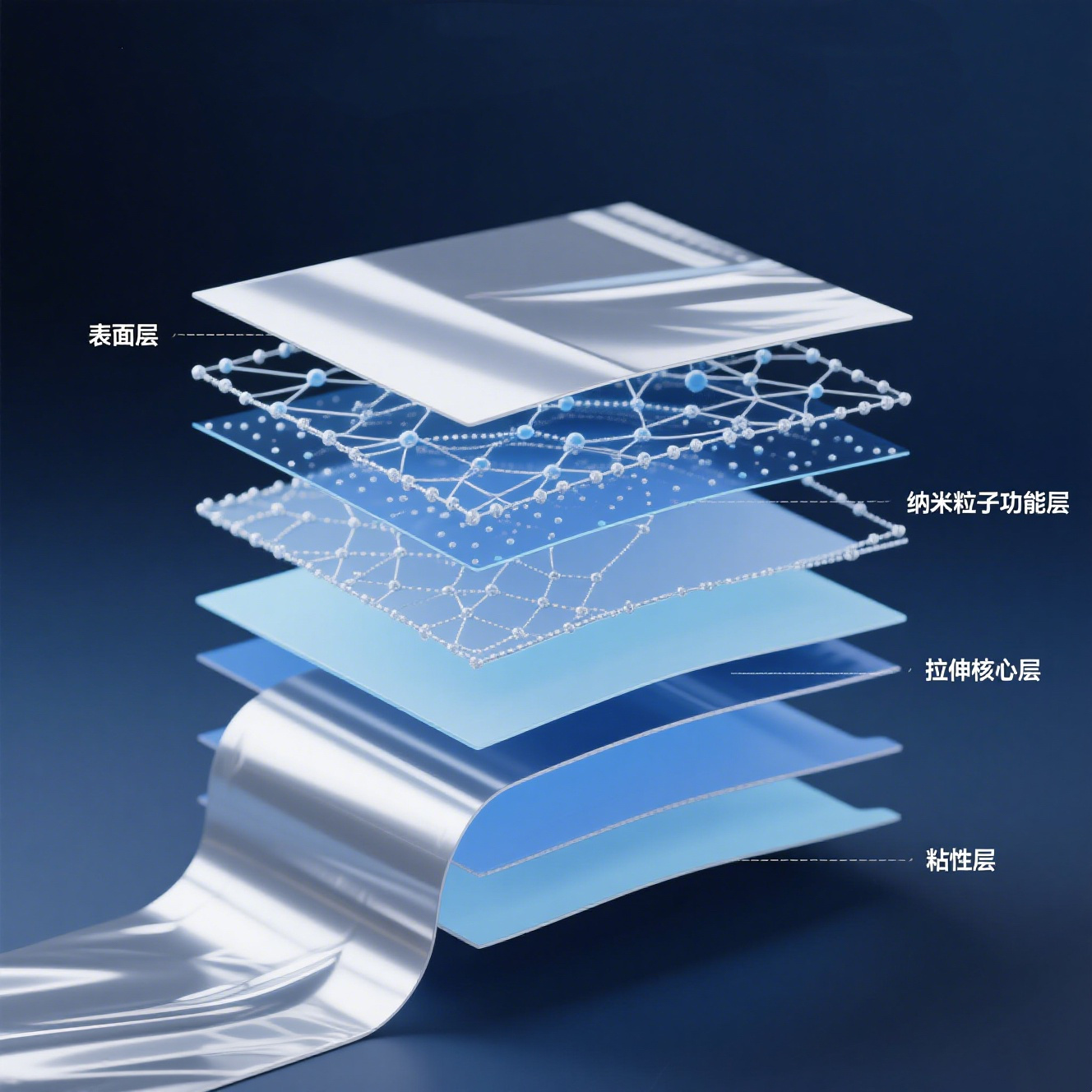

Multilayer coextrusion structure diagram:

[ Surface layer - Nanoparticle functional layer - Stretching core layer - Adhesive layer ]

Among them, the nano components are mainly distributed in the functional layer or core layer, forming a physical and chemical crosslinking network with the matrix polymer to improve the overall performance of the film. / The nano components are mainly distributed in the functional layer or core layer, forming a physical and chemical crosslinking network with the matrix polymer to improve the overall performance of the film.

III. The Mechanism of Nanomaterials in Stretch Film

3.1 Mechanical Strengthening Effect

Nanofillers, as a "microscopic reinforcing skeleton", form an interaction force network with polymer chains, playing the following roles:

- Improve the breaking elongation;

- Enhance tensile strength and modulus;

- Inhibit stress concentration and prevent film breakage;

- Significantly improve puncture resistance and tear resistance.

For example, when LLDPE is added to 2wt% of nano SiO ₂, 30%~50% the tensile strength can be increased by

3.2 and the puncture resistance is almost doubled.

Improved Barrier Performance MMT Introducing platy or layered nanomaterials such as

and graphene can construct a "maze path", lengthening the diffusion path of water vapor or oxygen molecules and reducing the permeability. 3wt% When the amount of montmorillonite added is 60% , the oxygen permeability can be reduced

3.3 Thermal Stability and Photoaging Inhibition

- Nano TiO ₂, ZnO has excellent UV absorption performance;

- Nano Ag 、 CeO ₂ can delay the polymer thermal degradation reaction;

- Used in outdoor storage or marine environments, it can significantly extend the service life.

3.4 Surface Functionalization

- Antibacterial: Nano Ag 、 ZnO can destroy the bacterial membrane structure;

- Self-cleaning: Nano SiO ₂ constructs a rough hydrophobic interface;

- Self-adhesive: Nanoparticles adjust the polarity and surface energy of molecular chains to achieve directional and controllable adhesion.

- Introduction to Typical Nano-enhanced Materials

Nanomaterials | Size Characteristics | Main Performance Contributions | Remarks |

Nano SiO₂ | Spherical, 20~50nm | Enhanced mechanics, anti-aging, self-cleaning | Surface can be grafted and modified |

Nano TiO₂ | Plate-like, 20nm | Anti UV, anti-thermal aging | Can be compounded with ZnO |

Nano Ag | Spherical, 10~30nm | Antibacterial, antifungal | Dosage needs to be controlled to prevent toxicity |

Graphene | Single-layer thickness 0.34nm | Conductive, barrier, anti-counterfeiting | High cost, difficult to disperse |

Nano MMT | Layered flakes, thickness < 1nm | Gas barrier, enhanced structure | Often requires organic modification |

Nanocellulose | High aspect ratio, particle size 10nm | Mechanical enhancement, good transparency | Bio-based environmentally friendly material |

- Key Performance Improvements of Nano-wrapped Film

Project | Traditional PE Wrapping Film | Nano-enhanced Wrapping Film | Improvement |

Tensile Strength | 25~35 MPa | 35~50 MPa | ↑40% |

Puncture Resistance | 2.5~4.0 N | 4.5~6.0 N | ↑50% |

Oxygen Permeability | 2000 cc/m²/day | 800 cc/m²/day | ↓60% |

UV Shielding Rate | < 10% | > 90% (containing TiO₂) | ↑9 times |

Antibacterial Rate | < 5% | > 99% (containing Ag) | Strong bacteriostatic property |

Degradability | None | Controllable (with PLA, PBAT) | Environmental upgrade |

- Preparation Process and Industrialization Route

6.1 In-situ polymerization method

Nanoparticles are generated simultaneously in the polymer synthesis reaction, with good dispersibility and strong interface.

6.2 Melt blending extrusion method

Mainstream method, the nanofiller is mixed with the base resin and then made into a film through a melt extrusion equipment. Suitable for mass production and low-cost manufacturing.

6.3 Masterbatch method

First, high-concentration nanoparticles are made into masterbatch ( Masterbatch ), then diluted with the main material for use, which is convenient for metering and dispersion control.

6.4 Multilayer co-extrusion method

Constructing functional layers and structural layers, and directionally integrating functional nano-components and structural enhancement.

VII. Typical Industry Application Scenarios

7.1 Heavy machinery and building materials logistics

- Use high puncture strength nano-wrapped film to prevent puncture at the corners of equipment;

- Achieve low thickness and high wrapping force;

- Reduce cargo dropping and sliding during transportation.

7.2 Food cold chain and fruit and vegetable transportation

- Nano Ag 、 ZnO Thin film can be antibacterial and antiseptic;

- Extended shelf life 1~2 times;

- Used for packaging steaks, fish, and vegetables.

7.3 Intelligent warehousing and RFID Integration

Transparent conductive wrapping film (such as graphene enhanced) can be used for label identification and Internet of Things integration.

7.4 Aviation assembly / High-altitude transportation

- Nano barrier films are used for packaging perishable and moisture-sensitive goods;

- They resist gas permeation and mildew in high-humidity, low-pressure environments.

VIII. Case Analysis and Data Verification

Case 1: Nano SiO ₂enhanced 1~100nm stretch film used in metal industry transportation

Customer: A major industrial enterprise

Application: Steel bar bundling, nut bundling

Result:

- Bundling tension increased 40% , unit consumables reduced 15%

- Film breakage rate reduced during transportation 90%

- Annual savings in packaging costs of approximately 30 ten thousand yuan

Case 2: Biodegradable nano PBAT stretch film exported to Europe

Components: PBAT+PLA+ Nanocellulose

Features:

- Biodegradable, environmentally friendly, high barrier

- Passed EU EN13432 and BPI certification

- Used in packaging for exported coffee trays and furniture trays

- Current Challenges and Future Trends

Challenges | Countermeasures |

Particle agglomeration | Graft modification, ultrasonic dispersion |

Cost control | Optimize the proportion of nanomaterials used, develop inexpensive nano components |

Processing equipment adaptability | Develop special screw structures, reduce shear heat loss |

Safety and regulations | Strengthen nano-material residue detection and occupational safety standards |

Dual balance of high performance and environmental protection | Multilayer co-extrusion + Green nano combination |

Future Trend Outlook:

- Greening: Introduction of natural nanoparticles and bio-based materials.

- Functional integration: antibacterial + Intelligent + High barrier integration.

- Intelligent manufacturing: AI Assisted formula design, performance prediction.

- Microstructure visualization: using AFM/SEM/ Molecular dynamics assisted design.

- Global standardization: promoting nano stretch film in ISO 、 FDA 、 EU Unified certification system.

- Conclusion: Nano stretch film leads the way in packaging material innovation

As a fusion of traditional packaging materials and advanced nanotechnology, nano stretch film demonstrates strong comprehensive performance advantages and broad application prospects. It not only enhances the mechanical properties, barrier properties, and functionality of the film, but also provides new technological support for green packaging, intelligent logistics, and global supply chains.

With the continued decline in the price of nanomaterials, the gradual maturity of preparation processes, and the promotion of biodegradable packaging by environmental protection policies, nano stretch film will occupy a core position in the future packaging revolution. For enterprises, early deployment of this technological track means higher competitive barriers and stronger sustainable development capabilities.

Nano-wrapped film,Stretch film,Technology,Innovation

Previous

Previous

Latest News

2025-07-30

Nano-wrapped film: The engine of a new era of high-performance packaging

Chinafilm Group will provide a comprehensive and systematic introduction to the fundamental theory, key properties, material composition, preparation process, typical applications, current challenges, and future development direction of nano-wound film, helping readers gain a comprehensive understanding of the technical core and market potential of this disruptive material system.

2025-07-24

Research and Application of a Novel Soft Pouch Film

Chinafilm Group provides a comprehensive analysis of the new soft pouch film industry, covering its definition, core technologies, performance advantages, practical applications, typical cases, and future trends. This analysis offers a systematic cognitive framework and practical reference for material developers, packaging designers, brand owners, and end-users.

2025-07-23

Development and Prospect of Biodegradable Film Materials

Chinafilm Group will delve into the definition, types, R&D progress, application fields, and future development trends of biodegradable film materials, aiming to provide valuable reference for industry practitioners, researchers, and policymakers.

2025-07-18

Stretch film “not sticky enough” or “too sticky”? Understand the secret of stickiness in this article

Zhongmo Group comprehensively reveals the composition principle and common problems of cling film viscosity, and provides practical film selection suggestions and processing solutions to help you accurately select films, reduce losses, and improve efficiency.

2025-07-17

What should be paid attention to when using cling film packaging during the rainy season/high temperature weather?

As the last line of defense in packaging, the stability and weather resistance of stretch film directly affect the transportation safety and brand image of products. Therefore, rationally selecting stretch film with stronger weather resistance and taking corresponding measures in packaging and storage are key to improving packaging quality and reducing cargo damage rates.