09

2025

-

08

Label film: Small label, big effect

Author:

Chinafilm Group

I. Preface: Viewing the "Large Industry" from the "Small Label"

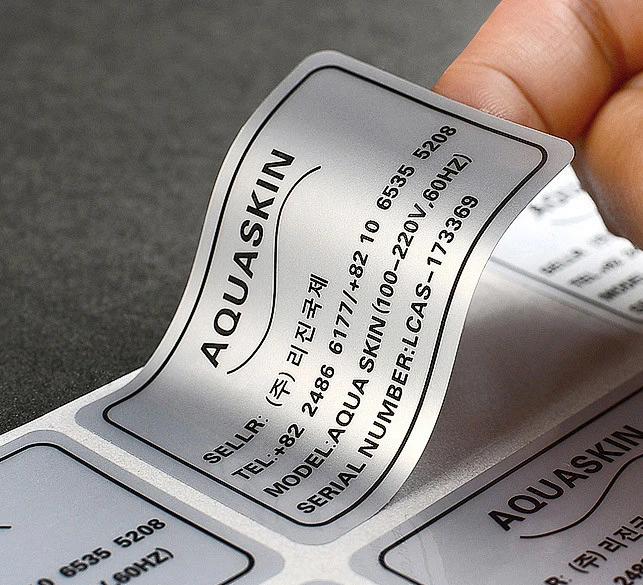

In modern commodity society, labels are everywhere. From beverage bottles on supermarket shelves, to barcodes on express packages, to instructions on medicine bottles, a small label carries multiple functions such as brand communication, product identification, information tracking, and anti-counterfeiting. As one of the core materials of labels —— Label Film Although thin, it runs through the nerve endings of the entire supply chain and industrial chain.

With the acceleration of the trend of packaging digitalization, greening, and high-end, the performance requirements of label films are increasing, and their application scenarios are becoming more extensive and specialized. This article will systematically introduce the main types of label films and in-depth analysis of their typical applications and technology adaptation strategies in different industries, allowing you to fully understand this “ The Great Effect Behind the Small Label ”。

II. Main Types of Label Films

Label films refer to film materials used to make the surface materials or functional base materials of pressure-sensitive adhesive labels. They have good printability, processability, weather resistance, and stability. According to different material properties, functional uses, and structural forms, label films can be roughly divided into the following categories:

2.1 Classification by Material

Label Film Type | Material Composition | Performance Characteristics | Application Fields |

PE Film (Polyethylene) | LDPE/HDPE | Good flexibility, can be applied to irregular surfaces, low-temperature resistant | Daily chemicals, mother and baby products, cold chain food |

PP Film (Polypropylene) | BOPP, CPP | High transparency, good stiffness, low cost | Food packaging, retail labels |

PET Film (Polyester) | Polyethylene terephthalate | Dimensional stability, high temperature resistance, chemical corrosion resistance | Electronics, home appliances, pharmaceuticals |

PVC Film (Polyvinyl Chloride) | Soft or hard PVC | Strong flexibility, UV resistance, good waterproofness | Building materials, power, cable labels |

Synthetic Paper Film | Polypropylene filled type | Paper-like appearance, waterproof and tear-resistant, writable | Education, logistics, instructions |

Decorative Films | Metal film, pearlescent film, iridescent film | Beautiful and atmospheric, enhancing brand recognition | Alcohol, cosmetics, gift packaging |

III. Application Analysis of Label Films in Major Industries

Different industries have different requirements for the physical properties, visual performance, and functions of labels, and the selection of label films must also “ be tailored to the specific needs. ” The following will analyze the specific applications and development trends of label films in key industries.

3.1 Food and Beverage Industry: Safety and Visual Appeal

Demand characteristics:

- High safety (food contact materials must comply with FDA 、 EU standards)

- Labels must be water-resistant, oil-resistant, low-temperature resistant, or high-temperature resistant (such as pasteurization)

- Strong visual impact to attract consumers to buy

Common film materials:

- Transparent BOPP Film : Suitable for transparent bottled products such as juice, dairy products, and tea drinks, showing the contents inside;

- White PP Film : Suitable for opaque bottles or cans, strong covering power;

- Freezing grade PE Film : Suitable for refrigerated and frozen products, no delamination or warping at low temperatures;

- Metal effect film (such as gold and silver dragon film): Enhance the high-end grade of food, such as wine and imported chocolate.

Application Cases:

A well-known dairy company, when launching a new yogurt product, used ultra-transparent BOPP Film +UV printing technology to present “ the bottle as media ” advertising effect, enhancing product display attractiveness, sales increased by 21%。

3.2 Daily Chemical and Personal Care Industry: Adhesion and Moisture Resistance are Key

Demand characteristics:

- Needs to adhere to complex curved surfaces (such as irregularly shaped bottles and tubes)

- Waterproof and moisture-proof, resistant to chemicals (detergents, shampoos, etc.)

- High aesthetic requirements, requiring high-precision printing or special effects

Common film materials:

- Flexible PE Film : Widely used for shower gel and shampoo bottles, with excellent adhesion;

- Pearl film, iridescent film Used for cosmetics or high-end personal care products to enhance the visual appeal of packaging;

- Transparent PET Film Combined with matte or gloss effects, it presents a delicate texture “ bare bottle ” Visual.

Application Cases:

A multinational personal care brand uses flexible white in its globally unified packaging PE Film replaces paper-based labels, improving waterproof performance while reducing label shedding during transportation, and improving customer satisfaction rates.

3.3 Pharmaceutical and health product industry: Durability and compliance are prioritized

Demand characteristics:

- Precisely identify drug information to prevent mismatches

- Adapt to special processes such as cold chain transportation and sterilization

- Tamper-evident, anti-counterfeiting, and highly traceable

Common film materials:

- PET Film Suitable for high-temperature steam sterilization and cold chain environments;

- Synthetic Paper Film Barcodes can be printed and written on, used for prescriptions and medicine boxes;

- Fragile film, anti-peeling film Prevent drug counterfeiting and reuse.

Application Cases:

A pharmaceutical factory uses matte white PET Label film with special adhesive to achieve 0℃~+70℃ Stable adhesion in the temperature range, while supporting thermal printing of batch numbers and QR codes, realizing full life cycle traceability.

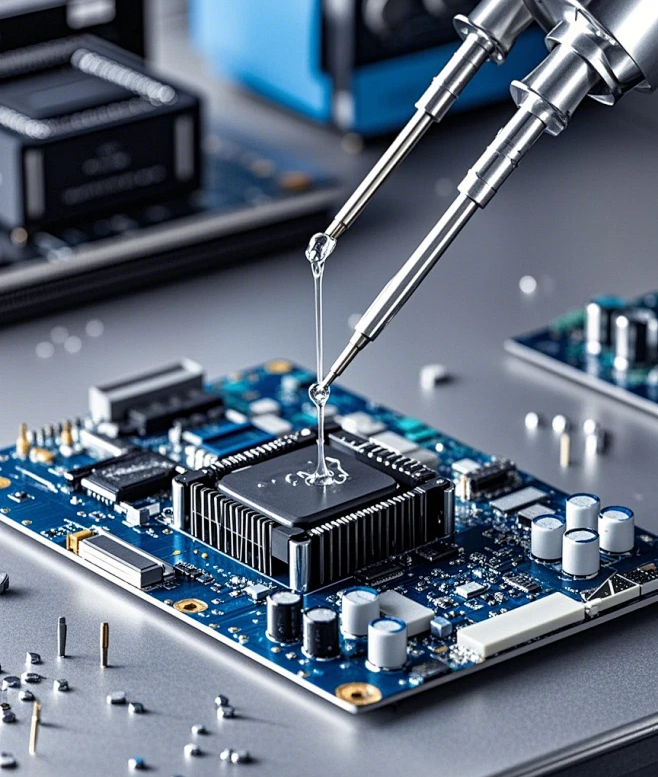

3.4 Electronics and electrical appliances industry: Functional film materials are showing their strengths

Demand characteristics:

- Strong dimensional stability, suitable for high temperature, humid or corrosive environments

- Some labels require UL 、 RoHS And other certifications

- Supports laser engraving and automatic labeling

Common film materials:

- High temperature PET Film Used for PCB Circuit boards, LED Module labels;

- Flame retardant PVC Film Used for internal safety labels of home appliances;

- PI (Polyimide) film Used in extreme high-temperature conditions ( 300℃ above);

- Double-layer peelable film Used to reveal hidden information during after-sales maintenance.

Application Cases:

A mobile phone manufacturer uses temperature-resistant film in battery labels PET Film ( 140℃ ), and adds an explosion-proof pressure-sensitive layer to improve the overall safety level and meet EU CE Certification requirements.

3.5 Logistics and e-commerce industry: Cost and efficiency are balanced

Demand characteristics:

- Fast printing, batch automatic labeling

- Low cost, good wear resistance, no shedding

- Clear barcodes, high readability

Common film materials:

- Thermal transfer synthetic paper film Direct printing, no ribbon required, suitable for large-scale express delivery waybills;

- PE Film Suitable for softer packaging, flexible and close-fitting;

- Waterproof PP Film Suitable for humid or long-distance transportation environments.

Application Cases:

A certain e-commerce warehouse has a daily shipment volume exceeding 10 Ten thousand pieces, switching to high-speed thermal film materials instead of traditional label paper, saving carbon ribbon consumption 30% , improving printing speed 25%。

3.6 Industrial and construction fields: Durability and identification performance dominate

Demand characteristics:

- Needs to resist ultraviolet rays, acids, alkalis, and weathering

- Long-term adhesion to rough or outdoor surfaces

- Labels do not fade, curl, or peel off

Common film materials:

- PVC Film Used for cable, wire, and distribution box labels;

- Metallized PET Film Used for industrial equipment nameplates;

- PE Thick film Used for building materials, pipe identification, and construction safety labels.

IV. Customization trend and future development direction of label films

4.1 Personalized customization trend of label films

With the intensification of brand differentiation competition, label films are changing from “ General-purpose materials ” To “ Industry-customized solutions ” Transformation:

- Food industry customized oil-resistant films, explosion-proof films

- Pharmaceutical industry customized alcohol-resistant wiping films, anti-tampering films

- Daily chemical industry customized stretch films, matte films, etc.

4.2 Rapid rise of environmentally friendly and functional film materials

New trend | Application description |

Eco-friendly degradable film | Using bio-based materials such as PLA and PBS, meeting regulatory requirements |

rPET recycled film | Made from recycled PET bottles, green and recyclable |

Smart identification film | Integrated RFID chips or thermochromic inks for product tracking |

Anti-counterfeiting variable film | Supports micro-printing, laser coding, anti-tamper strips, and other technologies |

V. Conclusion: Small Labels, Big Impact

As an indispensable component of modern packaging systems, label films have undergone continuous technological development and industrial applications, evolving from a simple carrier material into a comprehensive solution integrating functionality, aesthetics, security, and intelligence.

Against the backdrop of consumption upgrades, environmental transformation, and the rise of digital printing, the future of label films is rapidly advancing towards high performance, low carbon, personalization, and multi-functionality. For brands, choosing the right label film is not just about enhancing packaging quality, but also a key link in connecting with consumers, improving efficiency, and safeguarding product value.

“ Small labels, big impact ” is no exaggeration.

Label film,Packaging

Latest News

2025-08-09

Label film: Small label, big effect

With the accelerating trend of digitalization, greening, and high-end packaging, the performance requirements of label films are increasing, and their application scenarios are becoming increasingly broader and more specialized. This article will systematically introduce the main types of label films and in-depth analyze their typical applications and technical adaptation strategies in different industries, allowing you to fully understand the "great role behind this small label".

2025-08-07

**Start of Autumn: Expect Steady Winds While Heat Persists—Be Alert**

Liqiu arrives as scheduled. It originates from the ancients' observations of the celestial phenomena and is closely related to farming. But don't think that Liqiu marks the end of the scorching heat; the "autumn tiger" may still be lurking. Want to know how to adapt to the season and nurture your body and mind during Liqiu? This article provides a detailed explanation.

2025-08-05

Applications of nanotechnology in thin films

Chinafilm Group aims to systematically analyze the typical application mechanisms and performance improvement pathways of nanotechnology in thin films. Combining case studies and data analysis, it explores its broad prospects in various industries.

2025-08-01

Army Day|Salute to the People's Liberation Army of China

Chinafilm Group pays tribute to the Chinese People's Liberation Army

2025-07-30

Nano-wrapped film: The engine of a new era of high-performance packaging

Chinafilm Group will provide a comprehensive and systematic introduction to the fundamental theory, key properties, material composition, preparation process, typical applications, current challenges, and future development direction of nano-wound film, helping readers gain a comprehensive understanding of the technical core and market potential of this disruptive material system.