13

2025

-

08

Printing and adhesive technology of label films

Author:

Chinafilm Group

I. Preface: Printing and Adhesion, the Dual Engines of Label Film Value

As the core material of pressure-sensitive adhesive labels, label film undertakes multiple missions, including information transmission, brand identification, and functional protection. In the label system, Printability determines the visual communication effect, Adhesive technology relates to its actual performance in end-use scenarios. The two complement each other, forming the application value of label film " Dual Pillars ”。

With the rise of digital packaging, flexible supply chains, and green environmental protection concepts, the market has placed higher demands on label films: not only must they " Print well " Stick firmly ” , but also " Last long " Peel cleanly " Look beautiful " Print clearly " Change quickly " Environmentally friendly use ” This article will systematically discuss the mainstream printing processes, technological trends, and adhesive structure and control methods of label films, and present a complete picture of this seemingly small but highly engineered material system through application cases.

II. Overview of Label Film Printing Technology

2.1 Printing Characteristics of Label Film

The printing of label film is different from traditional paper labels. The key technical difficulties lie in:

- Smooth surface, weak ink adhesion

- The film material expands and contracts significantly with heat, easily causing printing deformation

- It needs to balance color reproduction, clarity, and scratch resistance

- It is often used in automatic labeling systems, requiring high dimensional stability

2.2 Comparison of Mainstream Printing Methods

Printing Method | Characteristics | Applicable Label Film | Advantages | Limitations |

Flexographic Printing (Flexo) | Mainly uses rubber plates, widely used in roll printing | PE/PP/PET, etc. | Low cost, fast speed, suitable for medium and large batches | Slightly lower precision |

Letterpress Printing (Letterpress) | Embossing type, suitable for small batches | Synthetic paper, paper-based film | Die-cutting integration, simple operation | Weak color layering |

Gravure Printing (Gravure) | Engraved rollers provide high-precision images | BOPP, PET film | Vivid colors, high precision | Long plate-making cycle |

UV Offset Printing (Offset) | Suitable for rigid label films | Synthetic paper, PET film | Fine colors, can be overprinted in multiple layers | Higher cost |

Thermal Transfer (TTR)/Thermal Printing | No plate making required, suitable for variable information | Synthetic film, thermal sensitive film | Flexible printing, fast response | Higher cost than large-batch printing |

Digital Inkjet | No printing plate required, suitable for small batch customization | Requires special coated film materials | Customization, diversity | Color fastness and cost remain challenging |

III. Label Film Printability Improvement Technology

3.1 Surface Treatment Technology

In order to improve the printing performance of label films, various pre-treatment methods are used to change their surface tension and roughness:

- Corona treatment : Improves film surface tension through high-frequency discharge, making ink easier to adhere (target surface tension ≥38 dyn/cm );

- Plasma treatment : Suitable for fine modification of high-resistance film materials;

- Coating treatment : Applying water-based / solvent-based coatings (such as white ink undercoating, UV overcoating) to improve adhesion and visual texture.

3.2 Development of Special Coated Printing Films

To adapt to UV inks, digital inkjet and other new ink systems, the market has developed a variety of special label film materials:

- UV Ink-compatible film materials : Can withstand instantaneous high-temperature curing without bubbling or shrinkage

- Digital printing film Surface coating features fast ink absorption, anti-bleeding, and quick drying;

- Water-based ink film Used for low- VOC ink systems in environmentally friendly flexographic printing equipment.

3.3 Multi-process composite design

With the increasing demand for diversified graphics, label films often use composite printing technology:

- Printing + Partial hot stamping

- UV Printing + Matte finish

- Double-sided printing + Transparent film layer

- Variable data printing + Anti-counterfeiting layer

IV. Analysis of Label Film Adhesive Technology

The label film's " adhesive ” properties, seemingly simple but actually complex, involve multiple factors such as glue formulation, substrate matching, and environmental adaptability.

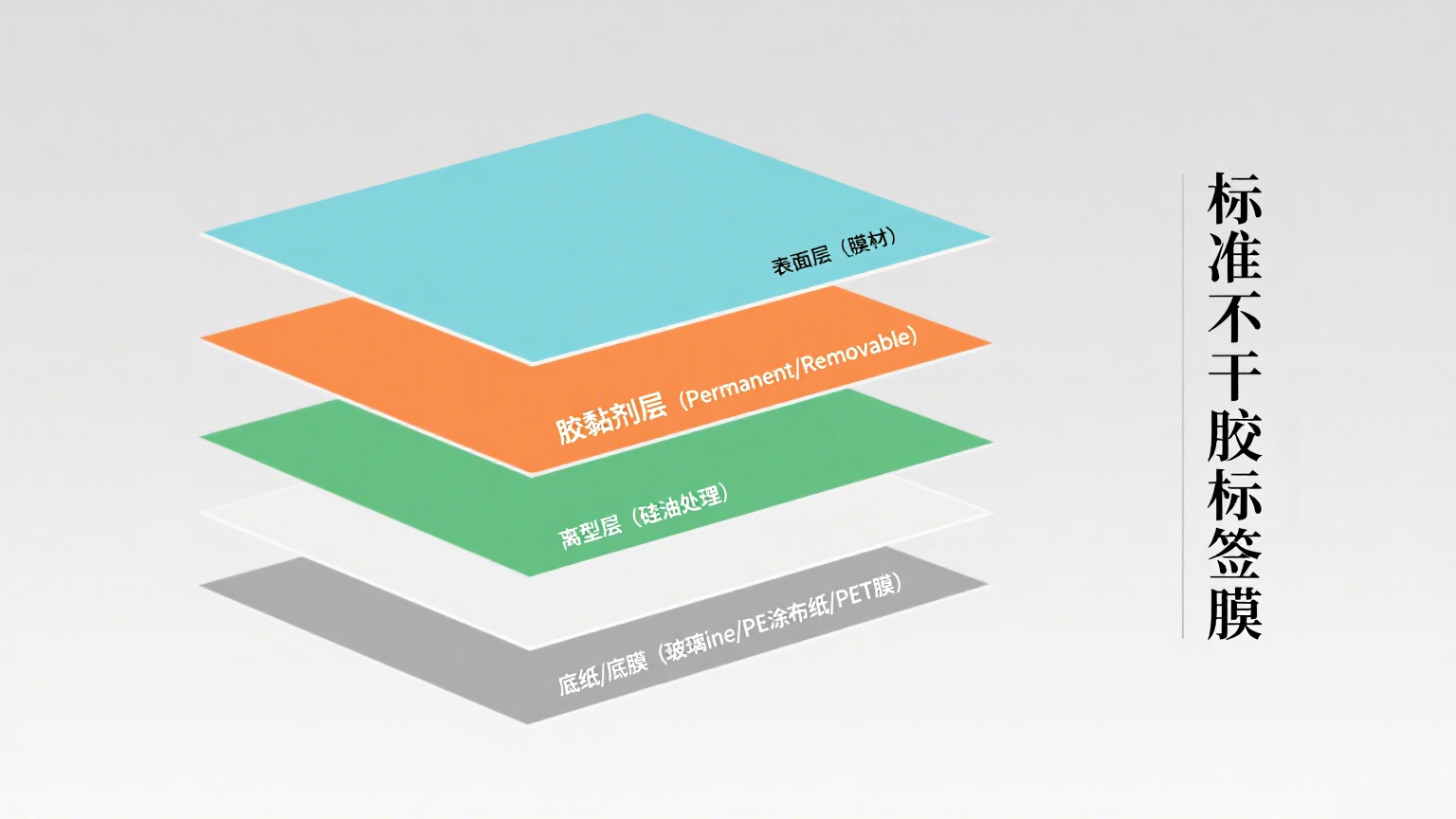

4.1 Label Film Adhesive Structure

Standard pressure-sensitive label films typically include the following layers:

- Surface layer (film material) ↓

- Adhesive layer ( Permanent/Removable) ↓

- Release liner (silicone oil treatment) ↓

- Backing paper /Backing film (glassine/PE coated paper/PET film)

4.2 Main Classification of Adhesives

Adhesive type | Characteristics | Application examples |

Permanent adhesive | Once applied, it cannot be peeled off again. | Supermarket goods, wine bottle labels |

Removable adhesive | Can be removed without leaving residue. | Window stickers, book stickers, price tags |

Cryogenic adhesive | Maintains adhesion at -40℃. | Cold chain transportation, fresh food |

High tack adhesive | Extremely strong initial adhesion, suitable for rough surfaces. | Chemical drums, building materials |

Tamper-evident adhesive | The label breaks or leaves a mark when peeled off. | Pharmaceutical seals, anti-counterfeiting labels |

Repositionable adhesive | Can be repeatedly applied. | Children's toys, electrostatic stickers |

4.3 Key Performance Indicators of Adhesives

- Initial tack Tack ) Adhesion when the label is first applied, affecting automatic labeling efficiency;

- Holding power Holding Power ) Long-term adhesion stability;

- Peel strength Peel Strength ) Force required for removal, related to whether residue is left;

- Shear strength Shear ) Resistance to label slippage;

- Weather resistance Resistance to moisture, heat, ultraviolet light, salt spray, and other external environmental influences.

V. Collaborative Design Principles of Printing and Adhesion

5.1 Adapting to Different Application Scenarios

Scenario | Printing technology | Adhesive type | Recommended film material |

Refrigerated labels | Flexographic printing + cold stamping | Low-temperature adhesive | PE film |

Cosmetics | UV offset printing + matte finish | High transparency permanent adhesive | Matte PP/PET |

Pharmaceutical labels | Thermal transfer + QR code | Anti-migration adhesive | PET white film |

E-commerce logistics | Thermal printing | Fast-bonding adhesive | Thermal paper |

Tire labels | Screen printing | High adhesion, high peel strength adhesive | Weather-resistant PE film |

5.2 Strategies for Avoiding Printing-Adhesion Conflicts

- Avoid contamination of the adhesive area by the printing area ;

- The printing ink layer should not be too thick to affect the flexibility of the label ;

- Avoid ink migration to the adhesive layer affecting adhesion ;

- Appropriate after printing " Ink conditioning ” to avoid curling due to uncured ink 。

VI. Typical Application Case Analysis

Case 1: Wet label application for beer bottles

Problem Condensation affects the stability of adhesion, causing labels to slip

Solution Use metallized PP film + High-humidity-resistant permanent adhesive + Flexographic printing + Matte varnish treatment to enhance bottle adhesion and brand visual consistency

Effect Complaint rate decreased 42% , longer lasting display in wine cabinets

Case 2: Pharmaceutical sealing labels

Problem Customers remove and reapply labels without authorization, affecting drug safety

Solution Use easily breakable PE film + Anti-peeling adhesive + Laser marking

Effect Visual anti-tampering, compliant with GMP standards, improving drug regulatory compliance

Case 3: Outdoor industrial steel drum labels

Problem Rough surface, labels fall off in wind and rain

Solution : PET film + High-viscosity acrylic adhesive +UV ink printing + High-gloss lamination

Effect Under high temperature exposure + and salt spray conditions, the service life is up to 1 years or more

VII. Future Trends and Technological Innovation

7.1 Rise of intelligent label films

- Temperature-sensitive / Humidity-sensitive ink Combined with special film materials to display temperature and humidity changes;

- RFID Label film Embedded chips for anti-counterfeiting and tracking;

- Variable data anti-counterfeiting film Supports QR codes and blockchain information integration.

7.2 Environmentally friendly adhesive technology

- Water-based pressure-sensitive adhesive (replacing solvent-based)

- Degradable adhesive layer design (with PLA and other biofilms)

- Washable adhesive layer technology (facilitating PET bottle recycling)

7.3 Standardization of digital printing label films

- HP Indigo 、 UV Inkjet and other platform-compatible film materials are being accelerated;

- Digital adhesive layer + Variable printing + Automated labeling integrated systems are rapidly forming.

VIII. Conclusion: Technological Accumulation, Value Emergence

The printing and adhesion of label films are not only a reflection of material technology, but also a fusion of packaging art and engineering wisdom. From process details to end performance, precise control of each " microscopic parameter ” can achieve macroscopic product safety, brand enhancement, and supply chain efficiency.

Against the backdrop of digital packaging, green packaging, and intelligent packaging, label films will continue to " invisible yet indispensable ” posture, undertaking the multiple missions of information transmission, aesthetic expression, value conduction, and functional expansion. In the future, whoever masters more stable, intelligent, and environmentally friendly label film printing and adhesion solutions will be able to grasp the voice in the global label industry competition.

Label film,Printing,Technology

Latest News

2025-08-15

Special Film Market: Growth and Innovation

Chinafilm Group will comprehensively analyze the logic, technological evolution, key applications, innovation paths, and global industrial landscape of the special film market, providing a systematic reference for understanding its future development strategy.

2025-08-13

Printing and adhesive technology of label films

Chinafilm Group will systematically explore the mainstream printing processes, technological trends, and adhesive structure and control methods of label films. Combining application cases, it will present a complete picture of this seemingly small yet highly engineered material system.

2025-08-09

Label film: Small label, big effect

With the accelerating trend of digitalization, greening, and high-end packaging, the performance requirements of label films are increasing, and their application scenarios are becoming increasingly broader and more specialized. This article will systematically introduce the main types of label films and in-depth analyze their typical applications and technical adaptation strategies in different industries, allowing you to fully understand the "great role behind this small label".

2025-08-07

**Start of Autumn: Expect Steady Winds While Heat Persists—Be Alert**

Liqiu arrives as scheduled. It originates from the ancients' observations of the celestial phenomena and is closely related to farming. But don't think that Liqiu marks the end of the scorching heat; the "autumn tiger" may still be lurking. Want to know how to adapt to the season and nurture your body and mind during Liqiu? This article provides a detailed explanation.

2025-08-05

Applications of nanotechnology in thin films

Chinafilm Group aims to systematically analyze the typical application mechanisms and performance improvement pathways of nanotechnology in thin films. Combining case studies and data analysis, it explores its broad prospects in various industries.